To meet the requirements of Swiss company Bühler with regard to its MHSA huller, Turck certified its contactless Li linear position sensor for use in the Ex area. The milling of oats and related products such as spelt, soya and sunflower seeds requires high throughput with minimum breakage.

The huller supplied by Bühler, the machine and plant builder headquartered in Uzwil, Switzerland, meets this requirement.

The long-established company was founded in 1860 and today has around 13 000 employees in 140 countries. As an innovative technology partner in the food industry, Bühler also demonstrates its expertise in this niche area with the MHSA huller. The company develops and sells process solutions and sustainable value chains for a wide range of industrial sectors. The group's operations are divided into the Grains and Food, Consumer Foods and Advanced Materials areas. The solutions arising from Grains and Food, which also includes milling solutions, ensure the production of safe and healthy foodstuffs. Each year, Bühler invests up to 5% of its sales in research and development and together with its customers and partners, forms a dynamic innovation ecosystem. Bühler strives to achieve market leadership in all its key industry segments. Its global market share in the milling sector is 65%.

Innovation and value creation

Bühler is a model Swiss company and continues to be a family-owned business. With its technical expertise and innovation capability it has gained an outstanding reputation among producers in the food and beverage industry, the automobile industry, as well as in several other sectors around the globe.

Bühler's strengths in the food and beverage industry lie in the fact that with its range of services it can cover and optimise entire value chains for greater efficiency. The seamless linking of subprocesses and the constantly increasing level of automation play a central role here. Bühler is also pursuing some ambitious goals with regard to sustainability. Major investments in digitalised solutions are designed to support customers in the reduction of waste, energy and water consumption in their value chains by 50%.

Procurement has a strategic importance for Bühler and is handled by its global supply chain network. The company engages suppliers who share Bühler's passion for innovation and actively participate in development processes in order to make a substantial contribution to increasing Bühler's competitive strength in global markets. However, the willingness of a partner to offer more than expected can also be a decisive factor.

Explosion risk from flour dust

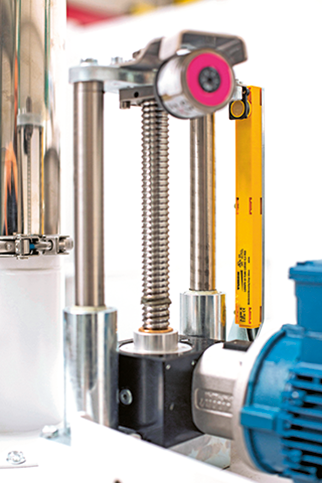

The process in which the MHSA huller is used is an environment with a dust-laden atmosphere. Flour dust can be explosive if there is a potential source of ignition in this atmosphere. These ignition sources can, for example, from electronic devices if they do not meet specific design requirements. The design engineers therefore required a contactless linear position sensor that is certified for the Ex zone 22. During the procurement process, Bühler's project manager, Vincent Behrens, discovered that most sensor suppliers were not able to provide an Ex certified sensor that was priced in the required range.

Bachofen: ready to give extra

It was then that Turck representative Bachofen, a long-standing supplier to Bühler, presented Turck's Li linear position sensor. Although this sensor met all the stated performance criteria, it did not at the time provide the necessary Ex certification. Bachofen encouraged Turck to take care of the necessary certification before the contract was awarded. This goodwill from its supplier was very well received by Bühler. Vincent Behrens said: “Due to experience with similar projects, the responsible product specialist at Bachofen predicted that certification would also be possible with this sensor type and took the necessary steps immediately. It was Bachofen’s flexibility, as well as its professional and active advisory support, that made this project so successful.”

Robust sensor solution

The measuring principle of Turck's Li linear position sensors is based on oscillation circuit coupling between the positioning element and the sensor. An output signal is provided here that is proportional to the position of the magnet. Thanks to its contactless operating principle, the robust sensors are both maintenance-free and wear-free. They offer an impressive performance due to their optimum reproducibility, resolution and linearity over a large temperature range. The innovative technology also ensures immunity to magnetic AC and DC fields.

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved