How to use edge computing in industrial IoT

February 2022

Industrial Wireless

Edge computing is a cloud environment located closer to automation-enabled devices at the edge of the network rather than at the data centre. End-points are connected to the operational network and control centre via an IIoT (industrial-Internet-of-Things) gateway.

The addition of cloud computing resources to the IIoT gateway at the edge enables local storage and processing of data, which, when compared to centralised cloud computing, offers compelling benefits such as:

• Higher reliability – because data doesn’t need to travel to a central cloud, communication isn’t interrupted if the link is down.

• Lower latency and consumption of network resources, for the same reason.

• Better security and compliance with regulations, as data isn’t exposed when travelling over public links.

Cloud computing and virtualisation enable multiple applications to run simultaneously and independently on the same hardware. In the context of IIoT, this means that a single gateway can perform not only networking functions, but also host other functions that are related to industrial applications and IIoT management.

The end result is less ‘boxes’, as fewer networking and IIoT devices are required. This also means better security, as the function that needs to be secured is virtualised within the securely connected IIoT gateway itself. All this means that edge computing provides the required insight and agility and at the same time reduces the number of devices that need to be deployed in remote sites.

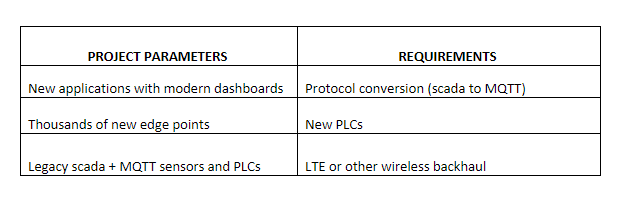

Where edge computing comes into play in new industrial IoT projects.

RAD’s SecFlow with edge computing and LoRaWAN has the capability to execute all of these requirements on the same hardware.

For more information contact Otto Wireless Solutions, +27 11 791 1033, [email protected], www.otto.co.za

Further reading:

Upgrading an outdated alarm monitoring system

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has successfully upgraded Guernsey Electricity’s MPAS90 alarm annunciator systems, which were first installed decades ago and are obsolete.

Read more...

Upgrading obsolete rack-based alarms

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has supported a major oil and gas company in Qatar by upgrading the obsolete MPAS 90 alarm systems at one of its major plants in the country.

Read more...

Würth Elektronik presents new radio modules

Industrial Wireless

Würth Elektronik has introduced two new highly compact radio modules. They give developers maximum freedom in designing proprietary wireless solutions that go beyond standard protocols.

Read more...

Senseca introduces data loggers to meet long range transmission needs

Senseca

Industrial Wireless

Senseca has introduced the driven LR35 data logger series based on LoRaWAN technology. They are specifically designed for situations where long-range transmission is required.

Read more...

Omniflex upgrades alarms for Uganda hydro plants

Omniflex Remote Monitoring Specialists

Industrial Wireless

Omniflex has worked with Uganda Electricity Generation Company to provide an upgrade solution for the plant alarm equipment across the Nalubaale and Kiira hydroelectric power stations on Lake Victoria.

Read more...

New RFID communication module

Siemens South Africa

Industrial Wireless

The new Siemens RFID communication module, Simatic RF128C enhances efficiency and flexibility, making it ideal for applications in the battery, electronics and semiconductor industries.

Read more...

Advanced missing person locator system to boost mine safety

Industrial Wireless

Becker Mining South Africa has enhanced its state-of-the-art Missing Person Locator system, a powerful module integrated into the company’s comprehensive SmartFlow digital mine visualisation and management platform, designed to enhance emergency preparedness and personnel safety in mining operations worldwide.

Read more...

New RFID communication module

Siemens South Africa

Industrial Wireless

The new Siemens RFID communication module, Simatic RF128C enhances efficiency and flexibility, making it ideal for applications in the battery, electronics and semiconductor industries.

Read more...

A South African legacy in telemetry

Interlynx-SA

Editor's Choice Industrial Wireless

Telemetry is becoming a vital component of industrial strategy, allowing companies to harness real-time data to optimise processes and reduce waste. One company leading this technological shift is Interlynx.

Read more...

Remote monitoring in remote and harsh environments

Omniflex Remote Monitoring Specialists

Industrial Wireless

For power grids, water supply networks and many industrial facilities, managing infrastructure in remote locations is a significant challenge. Omniflex discusses the requirements for remote monitoring equipment deployed in remote and harsh environments, and shares an example from the company’s work with a South African electricity supply company.

Read more...