Industrial digitalisation is a trend that is changing production operations in the oil and gas industry. One key branch in industrial digitalisation is process automation and control, where numerous sensors are used to measure the state of the process and collected data is transferred to data analytics software. The data is then analysed and optimal control parameters are sent to process automation systems. The digitalised process automation requires that the sensors and other automation systems are connected through a network. The performance and productivity of the plant can be improved by controlling the processes optimally, key for efficient resource use and essential for low carbon emissions.

Process automation requires an accurate measurement of the process state, but in the oil and gas industry, the real-time monitoring of the process has been a challenge due to the continuously changing process conditions. For example, the surface of the measurement sensor is typically contaminated by wax deposits and other materials that conventional sensors cannot measure through accurately. (More than 51% of separator failures are due to faulty level instrumentation.) Also, about 80% of global production is from mature assets, where challenging operating conditions makes timely, reliable data crucial.

Advanced sensors for process monitoring

Rocsole bridges this gap with the latest and most advanced process monitoring sensors. Now, the industry has access to reliable instrumentation with frequent data (typically 10 data points per second), designed to work in even the toughest operating environments. These sensors provide unique insights from critical processes like separators and settling tanks. This data is required for operators to optimise their production by correct handling of water-cuts, oil-in-water/water-in-oil emulsion layers, bitumen and rag layers, solid build-up and other process upsets. Further data analytics can be provided as a Data-as-a-Service (DaaS) model, which results in significant operational savings, where payback can, in some cases, be achieved in a matter of days.

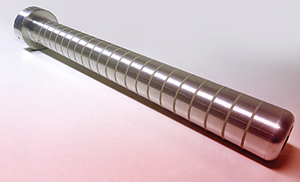

Electrical tomography

The measurement principle of the Rocsole sensors is based on electrical tomography. Here, completely safe low-voltage signals are used to scan the subject area of measurement. The measurement rates are high enough to enable the real-time monitoring of processes. Rocsole has industrialised the tomography technology widely used in the health-tech sector and made it compact, robust and of high enough resolution to be suitable for the type of operations encountered in the oil and gas industry. The sensors can tolerate high temperatures and pressures and the accurate measurement and data insights make it possible to optimise performance leading to more efficient energy and resource utilisation, with high uptime and less need for field services and maintenance. This ultimately supports the industry in the energy transition to carbon neutrality.

Going beyond this, Rocsole, with its connected IoT devices, can also assist operators remotely, which has shown to be very useful in pandemic times with all the associated travel and site visit restrictions. The company has done remote start-ups to help operators on their digitalisation journeys. As personnel do not need to be present on-site, this also contributes to a reduced carbon footprint in the range of 2-4 metric tonnes CO2 per installation. In the future, digitalisation will offer great new possibilities to process automation bringing the industry into a new era, both in terms of operational efficiency and low carbon emission efforts. For instance, deep learning algorithms will in future enable the effective utilisation of ever larger amounts of data (big data).

Rocsole’s approach to this is to utilise its own data, which could be from several sources (e.g., several separators in the production train, or several sensor points in one process vessel). The real-time data and databases can be used to predict the behaviour of the process, allowing every part of it to be controlled individually, reaching high overall performance levels and uptime. For team Rocsole, the most important mission is to make the industry safer and better for all, enabling the transition to low carbon and carbon neutral operations while at the same time operating safely.

| Tel: | +27 11 452 1390 |

| Email: | [email protected] |

| www: | www.seco-pi.com |

| Articles: | More information and articles about SECO Process Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved