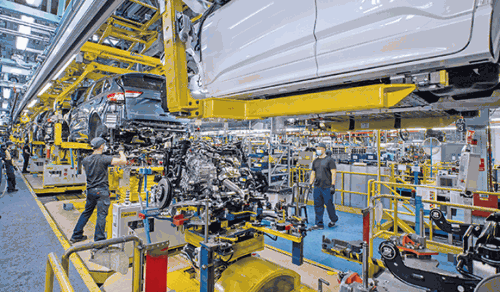

Henry Ford recognised the importance of maintaining strict quality assurance standards which have remained to this day, but car body construction is now more complex and multi-faceted. Quality assurance in modern vehicle production involves many rigorous procedures.

A particular challenge emerged in the production of Ford Kuga, which is manufactured alongside other models at Ford’s plants in Valencia, Spain. The actual work step involves welding a small, completely flat reinforcing sheet onto a larger assembly. “The machine operator inserts a large body shell component into a turntable before placing a smaller metal sheet on top,” explains Mario Eschweiler, manufacturing engineer Bodyside at Ford Europe. “It’s important at this stage to be able to recognise whether the smaller metal sheet is positioned correctly or not. Further, you also need to make sure that two or more of the reinforcing sheets have not been loaded inadvertently. During the next step, the turntable is rotated and a robot welds and removes both components.”

A task where camera systems give up

Due to this fixed production sequence, a conventional photoelectric distance sensor for presence detection was not an option. The reason: it would not have been possible to install the sensor without it getting in the way of machine operators or robots. When explaining the selection of suitable solutions, Eschweiler says: “Inductive and mechanical sensors were not suitable for the same reason. Single-sided inductive double sheet detection was ruled out due to the diminutive dimensions of the small part and also the associated positioning capability.”

In addition, strongly fluctuating lighting conditions caused by sunlight during the day and artificial light at night made the task even more difficult. “As initial tests showed, these requirements pushed conventional camera systems beyond the limits of their capabilities,” explains Eschweiler. “All in all, it was the perfect challenge for the PMD Profiler from ifm.”

The PMD Profiler reliably ensures correct usage and assembly of components. To do this, the optoelectronic line scanner projects a laser line on the working area that is being tested and determines the height profile by means of the reflected light. If the height profile matches the profile specified during teach-in, the PMD profiler detects a correct assembly. If the profile deviates beyond a definable tolerance, the sensor generates an error signal. With a measuring accuracy of 500 microns, the PMD Profiler detects even the smallest deviations, and thus, whether the thin reinforcing plate is missing, or if too many of them have been placed. Correct alignment of the component can also be tested by comparing the actual height profile with the specified height profile. The profiler’s working precision is matched by its tolerance in terms of its working environment: immunity to extraneous light, independence of distance, and flexibility in the positioning of the component along the laser line.

A technically robust solution

Both during a functional demonstration as well as in the actual test phase, the line scanner convinced the project participants at Ford. The result: “By using the PMD Profiler, we have been able to solve the task in a technically proficient way, thereby effectively minimising downtime through reliable error detection,” says Eschweiler. “Today, the task is solved for continuous operation. This point is underlined by the fact that the number of errors per thousand was just 0,2 during the first month of regular operation. These were real incorrect loads, correctly pointed out by the profiler.”

Conclusion

With the PMD Profiler, Ford was able to ensure the quality of the manufacturing step. However, the German project manager attributes that to more than the high performance level of the line scanner alone: “We experienced consistent, competent and personal support from the industry experts of ifm throughout the entire project – both here in Germany and also on site in Spain. That is also a crucial factor as I see it, which contributed to finding the ideal solution and implementing it successfully.”

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved