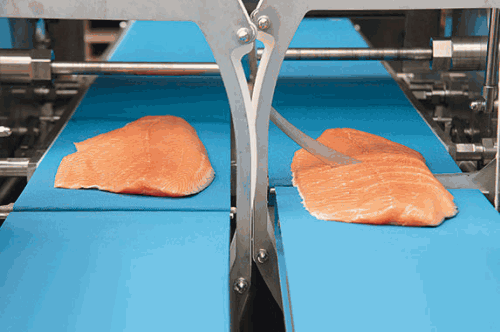

Danish company Borncut A/S, located in Rønne, has developed what it believes to be the world’s fastest and most precise portion cutter for the food industry, based on specially developed software and the open control platform from Beckhoff. Fish or poultry is divided into exact portions in a flash – with knives that rotate at speeds of up to 200 km/h and can make over 2100 cuts per minute.

The Borncut Scancut 225 portion cutter can process up to 4 tons of fish in just one hour to produce almost any number of individual pieces, cut to the desired weight. Speed and precision are key competitive parameters in the food industry, since even a small increase in processing performance can result in significant annual cost savings. Gorm Sørensen, co-founder and CEO of Borncut, gives an example: “A processing challenge arises when foods such as fish and poultry are irregular in size and shape. If, for example, 10 tons of salmon are processed per day, a machine output optimised by only 0,5% can save around DKK 5000, which adds up to around DKK 1,25 million – or around 170 000 Euros – per year.”

Fast EtherCAT communication increases machine performance

Peter Mikkelsen and Gorm Sørensen founded Borncut in 2016 with the aim of developing the most innovative portion cutter on the market. “With all due modesty, we have achieved our ambitious goal,” says Mikkelsen. “The tremendous machine speed is primarily due to the high performance of EtherCAT communication. This is because EtherCAT enables the control components in the machine, the PLC, servomotors, safety module, and our own high-speed camera, to communicate with each other very rapidly. This results in an extremely efficient process flow. At the same time, our machine requires minimum manual intervention since it uses network-compatible standard solutions.”

Borncut machines are available in single or dual lane versions, i.e., with one or two infeed belts. The corresponding setup can easily be changed via the CP27xx multi-touch panel PC. The machine can be adjusted exactly to the desired portion size using drag-and-drop functions. In addition, the machine data can be called up as required for comparison with other production data.

A special feature is the integrated high-speed camera that scans the food on the belt. The camera captures 250 frames per second and displays a 3D image on the panel PC. In this way, the end user can see exactly where the cuts are made. Mikkelsen elaborates: “The faster the volume of the fish or poultry can be calculated, the faster the food can pass through the machine. For example, in order to obtain only the best pieces, or to cut the fish into different sizes, the cutting blades can be conveniently adjusted using the drag-and-drop function, and the cuts can be accurately checked based on the 3D image.”

Reliable machine operation is crucial

Borncut places high demands on the control platform, especially with regard to operational reliability and service. This is because the machines are used for a wide range of different food production processes, and it is therefore important that they can reliably and quickly be adapted to new functions without equipment downtime. A standstill would have significant consequences for the end users, as the machines are often part of large processing lines with many operators. In addition, the food to be processed usually has a short shelf life at normal temperatures, and short delivery times are essential. Should a machine failure occur, it is crucial that the fault can be quickly located and rectified.

Sørensen concludes: “PC-based control from Beckhoff enables us to build efficient and reliable machines. The openness of the system makes it easy to integrate third-party components such as the high-speed camera, which gives us additional options. Another key factor is our good cooperation with Beckhoff, who took note of our requirements right from the start. Beckhoff staff were quickly available on site when the need arose and offer excellent service. The innovative solutions perfectly complement our own philosophy.”

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved