A new approach to wireless networks

June 2020

Industrial Wireless

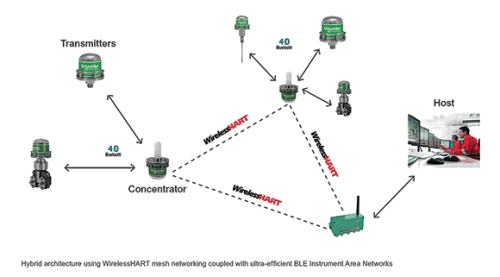

The Instrument Area Network (IAN) has been developed by Schneider Electric as a cost-efficient and flexible industrial wireless network as an alternative to more costly systems. Bluetooth communication between the field sensors and data collectors saves battery life and makes the network flexible and easy to install, giving users a cost-effective solution.

How it works

The IAN system consists of wireless field sensors for measuring absolute and relative pressure, differential pressure and temperature. These measurements can be linked via Bluetooth to the central collectors. These collectors collect the measurement data from a maximum of 8 wireless field sensors and send them via WirelessHART to any system.

By choosing Bluetooth between the field sensors and collectors, the batteries of the field sensors last longer than with a complete WirelessHART system. Local configuration is also easier to do with an app for a phone or tablet, using Wi-Fi. This makes Schneider Electric’s Instrument Area Network a cost-effective, user-friendly and flexible wireless system.

Differential pressure measurement: the WDP10 differential pressure sensors measure the differential pressure of various industrial processes and then transmits the PV wirelessly via Bluetooth to a central collector (WCC10). This sends the values from multiple sensors via WirelessHART to any central system. There are versions with differential pressure ranges up to 500 mbar, 2,1 bar or 21 bar. The field sensors are explosion-proof and have ATEX certification.

Gauge pressure measurement: the WAP10 absolute or gauge pressure sensors measure the pressure of various industrial processes and transmit them wirelessly to a central collector (WCC10). This sends the values from multiple sensors via WirelessHART to any central system. There are versions with pressure ranges up to 2,1 bar. The field sensors are explosion-proof with ATEX certification.

Temperature measurement: there are RTD and thermocouple versions from -200°C to 885°C, with various insertion lengths between 50 and 400 mm. Optionally, thermowells in various lengths can be supplied. The field sensors are explosion-proof according to ATEX

Further reading:

Upgrading an outdated alarm monitoring system

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has successfully upgraded Guernsey Electricity’s MPAS90 alarm annunciator systems, which were first installed decades ago and are obsolete.

Read more...

Upgrading obsolete rack-based alarms

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has supported a major oil and gas company in Qatar by upgrading the obsolete MPAS 90 alarm systems at one of its major plants in the country.

Read more...

Würth Elektronik presents new radio modules

Industrial Wireless

Würth Elektronik has introduced two new highly compact radio modules. They give developers maximum freedom in designing proprietary wireless solutions that go beyond standard protocols.

Read more...

Senseca introduces data loggers to meet long range transmission needs

Senseca

Industrial Wireless

Senseca has introduced the driven LR35 data logger series based on LoRaWAN technology. They are specifically designed for situations where long-range transmission is required.

Read more...

Omniflex upgrades alarms for Uganda hydro plants

Omniflex Remote Monitoring Specialists

Industrial Wireless

Omniflex has worked with Uganda Electricity Generation Company to provide an upgrade solution for the plant alarm equipment across the Nalubaale and Kiira hydroelectric power stations on Lake Victoria.

Read more...

New RFID communication module

Siemens South Africa

Industrial Wireless

The new Siemens RFID communication module, Simatic RF128C enhances efficiency and flexibility, making it ideal for applications in the battery, electronics and semiconductor industries.

Read more...

Advanced missing person locator system to boost mine safety

Industrial Wireless

Becker Mining South Africa has enhanced its state-of-the-art Missing Person Locator system, a powerful module integrated into the company’s comprehensive SmartFlow digital mine visualisation and management platform, designed to enhance emergency preparedness and personnel safety in mining operations worldwide.

Read more...

New RFID communication module

Siemens South Africa

Industrial Wireless

The new Siemens RFID communication module, Simatic RF128C enhances efficiency and flexibility, making it ideal for applications in the battery, electronics and semiconductor industries.

Read more...

A South African legacy in telemetry

Interlynx-SA

Editor's Choice Industrial Wireless

Telemetry is becoming a vital component of industrial strategy, allowing companies to harness real-time data to optimise processes and reduce waste. One company leading this technological shift is Interlynx.

Read more...

Remote monitoring in remote and harsh environments

Omniflex Remote Monitoring Specialists

Industrial Wireless

For power grids, water supply networks and many industrial facilities, managing infrastructure in remote locations is a significant challenge. Omniflex discusses the requirements for remote monitoring equipment deployed in remote and harsh environments, and shares an example from the company’s work with a South African electricity supply company.

Read more...