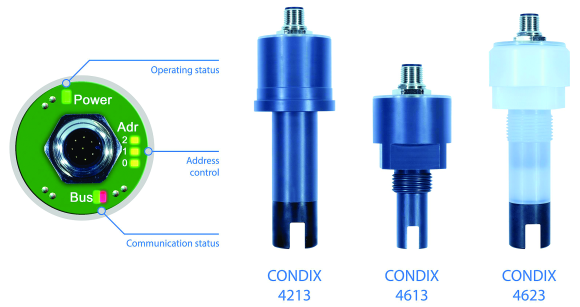

Condix is a low maintenance, easy to install measuring transducer that saves time and money. This solution for monitoring of conductivity in liquids does not require a separate measuring transducer nor an expensive special cable or indicator. It integrates directly into superordinate systems such as SAPS and scada via the universal Modbus RTU interface.

“The new and recently launched Condix from Martens determines the conductivity of liquids and the measured ohmic resistance provides information about the ion concentration in the electrolyte,” commented Jan Grobler, managing director of GHM Messtechnik South Africa, the local distributor for the GHM Group. “The integrated transducer converts the signal into a digital process value and further scaling in the subordinate system is not required.”

The universal Modbus interface enables convenient configuration and calibration of the measuring transducers. Standard fittings are utilised and parameterisation prior to field installation is easily carried out via a PC tool at the work station.

“Conductivity of water is an important parameter because it measures the ability to pass electrical current,” commented Grobler. “This is important in industries such as brewing, pharmaceutical and food manufacturing. The monitoring of water preparation, reverse osmosis and ion exchanger systems, in salt water, underground water preparation on ships, gas scrubbers and landfill seepage water for example, can also benefit from this new transducer technology.”

Intelligent diagnostics

Condix provides Industry 4.0 functions that are useful for intelligent self-diagnosis, more efficient maintenance, reduced downtime and a longer sensor life. With integration of the transforming electronics and the implementation of a digital interface, the sensor provides information about its status such as the internal sensor voltage and additional device parameters, in addition to conductivity and temperature measuring variables.

Advantages include:

• Robust technology in a compact design.

• The measuring transducer is integrated in the sensor and has a direct connection to the SPS.

• Less cabling means less installation work.

• All levels up to the PLC can be connected with one bus cable.

• 4-electrode measuring cell: resistant to polarisation effects.

Condix is an example of the advancement of Marten’s industrial analytical measuring technology. The integration of a digital interface supports conductivity measurement in the world of Industry 4.0. “We believe that this instrument will deliver high quality monitoring affording users more precise conductivity readings,” concluded Grobler.

For more information contact Jan Grobler, GHM Messtechnik South Africa, +27 11 902 0158, info@ghm- sa.co.za, www.ghm-sa.co.za

| Tel: | +27 11 902 0158 |

| Email: | [email protected] |

| www: | www.senseca.com |

| Articles: | More information and articles about Senseca |

© Technews Publishing (Pty) Ltd | All Rights Reserved