The ILM-4 conductivity sensor with IO-Link is a big step towards Industry 4.0 in hygienic process technology. It is equipped with both digital and analog interfaces in parallel. Data can therefore be transmitted digitally simultaneously with 4…20 mA technology.

Proven industry standard now also for hygienic and aseptic applications

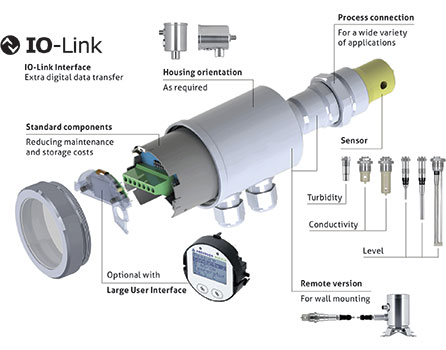

IO-Link offers advantages in process control and monitoring. The ILM-4 conductivity sensor, the first of a whole range of measuring instruments to be equipped with an additional IO-Link interface, is a well known and proven conductivity sensor on the market. This will be followed in due course by the sensors ITM-51 for turbidity, NSL-F for level, L3 for pressure and D3 for differential pressure and volume, all based on the modular platform with fail-safe plug-and-play technology with standard cable for time and cost saving installation and set-up.

The (r)evolution of conductivity measurement

IO-Link offers significant advantages over analog technology when it comes to reliably controlling the entire process technology with many measuring points, control and operating elements. Set-up and installation are easy and cost effective. A three-pole standard cable is sufficient for the signal transmission and power supply itself. In practice, point-to-point connections are made at field level from various sensors to collection points, IO-Link masters, and from there via fieldbus system to the control centre.

Simple data transfer becomes intelligent communication

With IO-Link, data streams in the opposite direction towards the sensors are now also possible. In this way, the status of the sensor can be checked and specifically queried at any time. This makes it possible to detect potential faults, signs of wear or an increased risk of failure at an early stage and helps to avoid production downtimes.

Plug-and-play takes on a whole new meaning

Sensor replacement of the ILM-4 with IO-Link becomes easier and safer than ever before and can be carried out independently, at any time and by any employee, without any programming effort. The device configuration of each connected sensor can be stored in the IO-Link Master. Immediately when plugged in, the new sensor is automatically recognised, configured and parameterised by the IO-Link Master.

New dimension in hygienic measuring technology

The ILM-4 conductivity transmitter with IO-Link creates planning security and flexibility for status control and the sensor diagnostics for preventative maintenance avoids production downtime. The combination with the modular platform, with the separation of the sensor and electronic unit in the optional remote version, creates a unique constellation of hardware and software that is unparalleled in flexibility, simplicity and system compatibility.

| Tel: | +27 21 557 9011 |

| Email: | [email protected] |

| www: | www.mortoncontrols.co.za |

| Articles: | More information and articles about Morton Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved