Medical engineering devices are evolving quickly and accompanying requests to the suppliers of device components are becoming increasingly complex. Optris reacts to this through regular improvement and adjustment of its sensors for non-contact temperature measurement.

Medical devices are invariably small and compact. Therefore, the construction of the temperature sensors is an important requirement for their use. Through constant exchange with customers, Optris has been in the position to optimise the Optris CS LT for medical technology.

Due to its length of only 87 mm and a diameter of 12 mm, the Optris CS LT fits perfectly into the smallest medical devices and products. The Optris CSmed LT is a special version of the device, which offers a significant advantage to the user: a short connecting cable with a plug. This allows fast and simple fitting or removal of the thermometer, e.g. for regular calibrations.

Temperature control in cryo-technology

The Optris CS LT finds regular use within the medical technology, for applications such as cryo-technology (also known as the low temperature technology) used to generate temperatures within the range around -150°C.

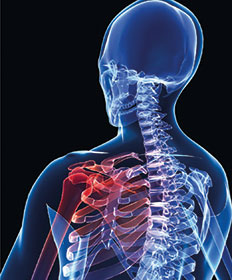

This technology is used for treatments such as cold shock therapy used for sports injuries, swellings, inflammation, bruises or muscle stiffness, as well as oedema, haematoma or scar tissue. It enables inflammation spots to be dismantled faster reducing pain and swelling.

One medical OEM customer of Optris is using gas bottles with liquid CO2 gas for the thermo shock treatment. The pressurised liquid gas is released from the bottle and applied to the skin as dry ice. During this process, the skin of the patient is cooled from about 32°C to 2°C within 30 seconds. In order not to cause harm to the patient, permanent control is necessary during this process.

For an easy control of the temperature of the skin surface, the Optris CS LT is fixed in the pistol of the head unit and the measured surface temperature is shown on a display. Due to the wide temperature range of -40 to 1030°C, the sensor is perfectly suited to applications in cold shock therapy where skin damage must be prevented.

Thermoforming of dental products

Another important application of infrared temperature sensors in medical technology is the implementation of infrared thermometers in thermoforming devices that are used for the production of dental products.

An example would be a customer of Optris who is producing thermoforming units for dental laboratories. These units are used to produce individual adjusted mouthpieces for protection during sportive activities.

Ahead of the forming of the mouthpiece, infrared radiators heat the plastic foil to a defined temperature. High homogeneity over the surface and a proper adjustment of the reforming temperature will lead to high quality reforming results. Therefore, the temperature must be monitored to achieve product quality, and avoid local burning and crack formations.

In legacy machines, temperature is measured through contact sensors at the radiator. Recently, the company started using non-contact temperature measurement. The pyrometer Optris CS LT, installed underneath the infrared heater, captures the temperature of the foil during the heating process. The heating stops at a set temperature and then the thermoforming process begins.

| Tel: | +27 10 595 1831 |

| Email: | [email protected] |

| www: | www.instrotech.co.za |

| Articles: | More information and articles about Instrotech |

© Technews Publishing (Pty) Ltd | All Rights Reserved