In maintaining and managing industrial plants, monitoring wastewater pH/ORP is both a legal obligation and an unavoidable necessity for protecting the environment. Monitoring without an attentive eye can lead to severe consequences. If toxic substances happen to leak externally, not only will legal sanctions result in plant shutdowns, but also the firm’s image will suffer, and victims of pollution may require compensation. To avoid this, sites usually conduct patrols to take measurements of wastewater. However, many do this remotely because it can be difficult to reach some of the measuring locations, and there is potential for human error when recording the measured values. With the use of Yokogawa’s plant-wide Field Wireless as a pH/ORP monitoring solution, centralised management and accurate wireless measurements can be taken at each point remotely.

What is plant-wide Field Wireless?

Plant-wide Field Wireless is a wireless system employing the international ISA100 Wireless (IEC62734) industrial standard, giving it the reliability demanded of industrial wireless communication and real-time functionality. It utilises a redundant duocast technology that communicates with two access points simultaneously to maintain connection when a communication channel or access point fails. It is highly scalable, supports a variety of interfaces for connecting to the access points and upstream systems including Ethernet, wireless LAN, and optical Ethernet, and is flexible during structural plant changes, making it ideal for building large-scale wireless networks.

Solution and benefits

Directly sends data wirelessly without a power supply

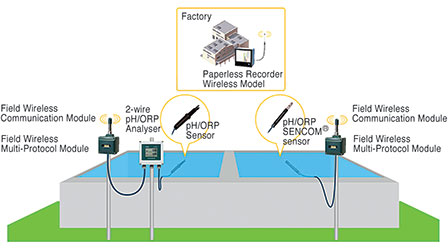

The minimum configuration for the pH/ORP meter is simply the pH/ORP Sencom detector series, the FN310 Field Wireless multi-protocol module, and the FN110 Field Wireless communication module. With wireless communication, data can be sent directly to access points, and because the access points are battery powered, no power supply is needed. The batteries last up to 10 years depending on operating conditions, and therefore almost no maintenance is required. Difficult-to-reach drainage channels and outlets can be easily measured remotely.

Covers up to 500 locations from up to 2 kilometres

The communication range is 500 metres, and monitoring can take place from a control room up to 2 kilometres away by installing relay stations. Up to 500 measurement points can be installed, offering excellent scalability. Even in large-scale plants, effluent measurements can be centrally managed.

Low entry cost

Wired solutions require installation with cabling, which costs time and money. By installing a wireless device at each measurement and relay point however, the cost is decreased.

Yokogawa’s solutions meet even more needs

Acquired data is aggregated on an upstream system for output to control screens or in report format that can be customised for the needs of the site. If a highly redundant system is required, Yokogawa recommends the FLXA21, a modular 2-wire liquid analyser that connects to two detectors. For easy measurement within the plant, installing a GX20W wireless recorder allows remote monitoring of data directly from field wireless instruments.

In conclusion

Conventional small field wireless systems are mainly installed as additional monitoring tools in areas with a clear line-of-sight such as tank yards and wastewater treatment facilities. Such systems offer only limited advantages such as improved inventory management, reduced regular visual checking, automated environmental measurement, and reduced wiring costs.

In contrast, plant-wide field wireless systems can cover both a large number of measuring points in a small area packed with production equipment where wireless devices are difficult to install, as well as the entire plant. This allows customers to set up wireless devices anywhere in their plants and manage data from those devices to improve plant-wide production efficiency.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved