Known condition of control valves and instruments can be utilised in maintenance planning to focus actions to the devices most needing attention. Traditional ways to diagnose control valves and instrumentation have either been by analysing the digital valve controller’s and instrument’s device information, or by testing and analysing with portable testing tools. Metso Flow Control’s ValveTriage Service, a new way to evaluate the device condition and performance utilising process information. This is especially tempting for plants not having modern digitalised device technology with associated systems or possibilities and resources for the portable testing.

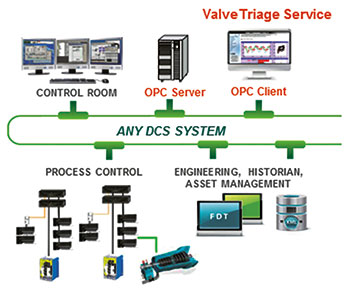

Control systems are gathering real-time data from all corners of the plant. The data can be stored and used to analyse condition and performance of field devices. With ValveTriage Service, the process data can be turned into meaningful diagnostic information. The service system runs 24/7 gathering data from the control system via OPC interface. It calculates several diagnostic measures bringing up the devices needing attention. Typical diagnostic measures for control valves are excessive valve travel, oscillation due to valve stiction or hysteresis, and valve sizing issues. Respectively, data losses, instrument at limits, noise levels, spiking and flat lining are followed in the case of measurement instruments.

A great advantage of real-time metrics and diagnostics calculated from process data is that they can quantify the extent of the problem and its effect on the process. Rather than saying there is “some stiction” on a valve, exact numbers, such as 4,2% stiction causing 2,1% variation in the process value, can be supplied. This gives more value than a “true/false” diagnostic and severe problems will receive much higher priority. The prioritisation gets even more valuable when the real-time metrics are combined with a device’s criticality class information, i.e. the device’s impact on process, safety and the environment.

ValveTriage Service’s findings and maintenance proposals are reviewed with the customer’s maintenance representatives in order to define and prioritise maintenance actions. The focused actions greatly reduce time spent in the field, working on wrong problems, freeing up skilled personnel to resolve the right issues and spend time on higher level tasks.

As the number of maintenance activities go down, not only does the cost of maintenance fall, but it also makes the plant safer resulting in fewer events for potential faults and accidents. The ValveTriage Service delivers bottom-line results by focusing attention to the worst behaving devices. Lifetime of equipment is extended by early detection of excessive wear and tear and process performance is enhanced by bringing down process variations.

For more information contact Metso South Africa, +27 (0)31 502 9350, [email protected], www.metso.com

| Tel: | +27 31 502 9350 |

| Email: | [email protected] |

| www: | www.valmet.com/flowcontrol/ |

| Articles: | More information and articles about Valmet South Africa, Flow Control |

© Technews Publishing (Pty) Ltd | All Rights Reserved