Yaskawa and Vipa present motion control in the PLC

May 2016

PLCs, DCSs & Controllers

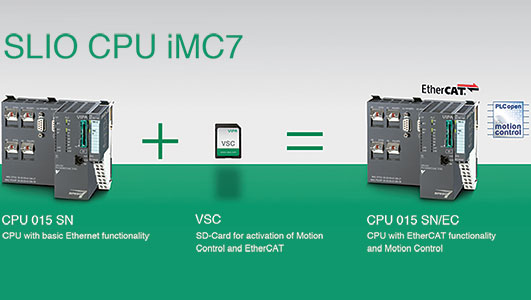

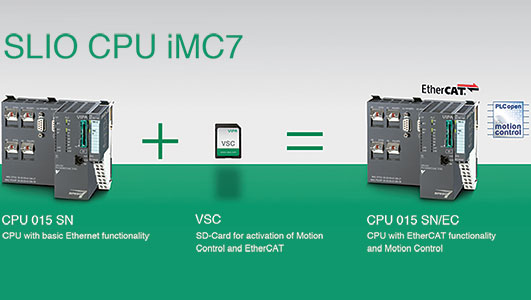

Yaskawa and Vipa have jointly introduced the SLIO CPU iMC7, which allows the direct implementation of motion control functions in the PLC. The communication between the Vipa SLIO CPU and the Yaskawa drives runs via EtherCAT. For the configuration of such control, the Vipa engineering tool Speed7 Studio was extended by adding the Yaskawa Sigma-7 motion control modules.

The new CPU iMC7, based on the existing standard functions of the CPU 015, allows PG/OP communication, functions blocks, supported protocols of the Ethernet communication and the configuration of the CPU, via the VIPA Set Card (VSC). Additionally the motion control functions and EtherCAT are also configurable via the VSC. An important aspect for universal applicability is the presentation of the Step7 function block in a similar format to the PLCopen motion function blocks. This defines a library of function blocks for motion control, which includes the functions of single axis or axes groups. EtherCAT is also the communication protocol for data exchange between the PLC CPU and the motion control modules.

The revised version of the programming and configuration tool allows direct configuration of the fieldbus between the CPU iMC7, the drives and the I/O. For this, the Yaskawa drive modules are accessed directly from the integrated hardware catalogue and then transferred via drag-and-drop into the hardware configuration. It is no problem to program the user application via the motion function blocks and to configure cam profiles, even if the user has little knowledge of the motion and drives world.

With the Sigma-7 series, Yaskawa sets standards regarding diversity, precision and reliability in drives technology. The series offers standard rotation motors as well as linear and direct drives. The auto-tuning functions allow the complete configuration of the servo-axis in a machine within less than two hours. The Sigma-7 servo drive solutions consist of servomotors und the servo amplifiers. Both components have exactly the properties necessary for optimal operation.

The drive solutions include motor power from 50 W up to 15 kW for rotation motors and peaks loads of 7560 N for linear motors. The optimised motor construction results in improved cooling, which implies energy savings of ca. 20%, since no additional cooling is needed at temperatures between 0 and 55°C.

For more information contact Terry Rosenberg, Yaskawa Southern Africa, +27 (0)11 608 3182, [email protected], www.yaskawa.za.com

Further reading:

Valmet’s automation powers world’s largest air-to-water heat pump

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system for Helen’s Patola air-to-water heat pump plant and two electric boilers currently being built in Helsinki, Finland. When completed, the air-to-water heat pump plant will be the largest in the world with a full heating production capacity around 30 MW.

Read more...

All eyes on the modern DCS platform

Schneider Electric South Africa

PLCs, DCSs & Controllers

Modernised DCS platforms are no longer confined to hardware-dependent architectures. These systems have evolved to combine the strengths of both PLCs and DCS while adding capabilities that make them more open, resilient and collaborative.

Read more...

Automation solution for waste management at incineration facility

PLCs, DCSs & Controllers

Valmet is to deliver an automation system to Seongnam City’s incineration facility currently under construction in South Korea. By leveraging intelligent automation, the plant will optimise energy production, minimise emissions and deliver efficient, consistent performance throughout its entire lifecycle.

Read more...

Valmet’s supplies DCS to Europe’s largest electric boiler plant

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system to Helen’s Hanasaari electric boiler plant and a thermal accumulator being built in Helsinki, Finland. Once completed, it will be Europe’s largest electric boiler plant.

Read more...

Technology blueprint paves way for e-methanol fuel expansion

Schneider Electric South Africa

PLCs, DCSs & Controllers

Schneider Electric has delivered the technology stack behind European Energy’s Kassø Power-to-Xfacility, the world’s first commercially viable e-methanol plant.

Read more...

PCS Global delivers turnkey MCC installation in Botswana

PCS Global

Editor's Choice PLCs, DCSs & Controllers

PCS Global is delivering a turnkey containerised MCC installation for a major copper mining operation in Northwest Botswana.

Read more...

New energy-efficient evaporation line for dissolving pulp production

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s €75 million project to convert the Biotek mill to produce dissolving pulp for the textile industry.

Read more...

Valmet modernises turbine automation

Valmet South Africa

PLCs, DCSs & Controllers

Valmet has received an order to deliver a comprehensive replacement of plant DCS and turbine control systems at Ennatuurlijk’s combined cycle power plant in the Netherlands.

Read more...

Hybrid DCS for an evolving industrial landscape

Schneider Electric South Africa

PLCs, DCSs & Controllers

Today’s industrial automation continues to evolve at a blistering speed, which means traditional DCSs have to keep up to ensure continuous integration into modern, digital infrastructure.

Read more...

IIoT controller for the field and control cabinet

ifm - South Africa

PLCs, DCSs & Controllers

The IIoT controller from ifm is a powerful, communicative and flexible PLC solution in machine and plant digitalisation.

Read more...