An Endress+Hauser customer producing more than 880 000 tons of heavy plate annually, was able to retrofit the Endress+Hauser wireless solution at a lower cost than expected. The producer is confident that it now has an optimum overview of the status of the roll neck bearings and that it can maintain the system and replace bearings according to schedule, regardless of any faults.

Every company has an interest in making sure that its processes are running at optimum levels. Incidents which cause a system to shut down may not only lead to costly repairs but may result in considerable losses. This heavy plate manufacturer optimises plant availability through recoding temperatures at the roll neck bearings and a straightforward implementation using WirelessHART.

The challenge

The four-high rolling stand at the manufacturer comprises of two work rolls which reshape the steel slabs directly, and two back-up rolls, which transfer toll pressure to the work rolls. The four-high stand has a maximum rolling force of 80 000 kN. This situation is very demanding, even for roll neck bearings. The roll neck bearings are located on the operating and drive side of the upper and lower back-up rolls. These are known as Morgoil friction bearings. A lubrication circuit ensures that the Morgoil bearings get the lubrication they need while the temperature of this circuit is monitored at the inlet and outlet.

An increase in the temperature differential indicates a higher degree of friction inside the bearings which may result in damage. However, the ambient conditions which prevail at the rolling stand make it difficult to wire up the necessary temperature sensors securely.

The solution

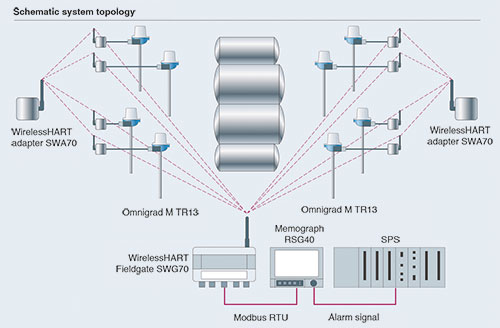

For temperature measurement, TR15 resistance thermometers with a weld-in thermowell and replaceable insert are used. These have already proven their worth a thousand times over in challenging industrial applications. Each temperature sensor is fitted with an adaptor which enables wireless data transmission based on the WirelessHART standard. Due to space limitations and possibly restricted radio communication, installing the adaptor directly on the temperature sensor is not advised. The adaptor is therefore installed remotely and connecter to the temperature sensor using a short cable. The adaptor not only facilitates data transmission, it also powers the connected device via the battery integrated in the adaptor.

Each adaptor works as a transmitter and receiver, ensuring the data can be transmitted to the WirelessHART gateway, even if direct radio communication is not possible. The WirelessHART gateway forms the central access point to the WirelessHART network and manages communications. The gateway automatically assigns the communication paths in the network as well as the times for the data packets. This means the new measuring points can be retrofitted easily.

From the gateway via Modbus RTU, the measured values are displayed on a Memograph RSG40 graphic display recorder. From there, they can also be transferred to downstream control systems. The eight measured values are monitored permanently. If a set threshold is exceeded, an alarm is triggered via the control system.

This solution ensures that, with little effort in installation and commissioning, any impending damage to the friction bearings is detected and a maintenance intervention is initiated in a predictive manner. This type of friction bearing, its installation and removal as well as the associated production downtime, is extremely costly. Please visit http://bit.ly/1Qwtdj5 for more.

The results

• Detection of any damage to the friction bearings.

• Predictive maintenance intervention.

• Protection of the costly friction bearings.

For more information contact Benjamin Mlangeni, Endress+Hauser, +27 (0)11 262 8012, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved