Compressed air is one of the most expensive forms of energy production in process industries. Many companies are not aware of the fact that the generation of compressed air accounts for up to 15 to 20% of total electricity use in their industrial facilities. Often, a significant amount of energy is wasted due to undetected air leaks, inappropriate usage, poor control, and inefficient equipment. This can add up to thousands of Rand in unnecessary energy costs every year.

Measurement of compressed air consumption is one of the important steps towards a cost-conscious handling of an expensive commodity. Identifying leaks, air consumption and compressor inefficiency can make a significant contribution to reducing energy costs. Yokogawa’s Vortex meter is one of the most accurate and effective ways of monitoring and measuring a compressor’s output and efficiency.

Yokogawa’s solution

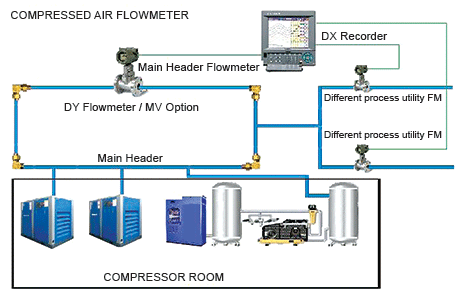

Yokogawa offers a complete solution for monitoring a compressed air system with the option of integrating the Vortex output signal into Yokogawa’s ISA100.11a wireless network devices. This provides a further cabling and installation cost saving.

The digital YewFlo Vortex flowmeter is accurate and stable, even in harsh process conditions. Its highly reliable and robust design delivers improvements in plant efficiency and reduces operating costs with minimal pressure drop. In addition, the digital meter with MV option comes with a built-in temperature sensor to get volumetric flow with temperature correction in order to optimise the monitoring of air flow. Advantages include:

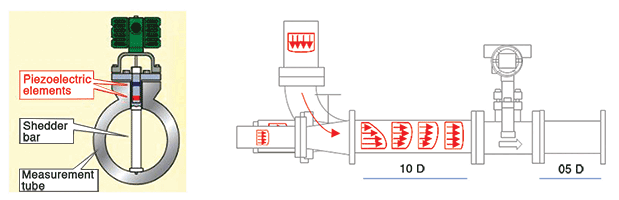

• With a dual Piezo, sensor construction coupled with spectral signal processing provides the ability to distinguish between noise and flow while ensuring accurate and stable low flow measurement.

• Features such as simultaneous flow and temperature output allow multi-variable detection. The unit contains no moving parts, requires minimal maintenance and has low impedance to the flow. Very low pressure drops can be expected and a stable accuracy is specified to less than 1,5% over a wide flow range.

• With installation of only 10D upstream and 5D downstream in the piping length, no additional flow conditioner is required.

• A clear, parallel two line LCD display indicates simultaneous flow rate and total flow along with process diagnostics. It is configurable through a display interface (MMI).

Yokogawa’s compressed air efficiency monitoring system identifies critical air leakages to prevent artificial air demand. In addition, the balancing of air production minimises maintenance costs and ultimately improves the quality of air.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved