The processing of ore always requires one key aspect of the equipment used – robustness. Measuring slurry flow is one of the most challenging applications. In the aluminium refining process, for instance, there are many difficult applications such as abrasive and adhesive slurries that contain corrosive chemicals. Magnetic flowmeters are the most popular for these applications. Performance and robustness are key to maximise plant availability and production with minimum total cost of ownership.

The aluminium refining process presents tough conditions when measuring slurry and corrosive chemicals:

• Abrasive slurries create fluctuations on the output signals and damage the liner and electrodes.

• Heavy slurry ‘noise’ causes measurement inaccuracy and instability.

• With correct application engineering, life expectancy of the measuring device will increase.

• Adhesion properties of high density red-mud are high, which causes build up on the electrodes requiring frequent cleaning and maintenance.

Yokogawa’s Admag variety and fit-for-purpose solutions, deliver stable and reliable process control in noisy slurry applications. At the same time, the robust and reliable mechanical design achieves long life span and reduces maintenance and downtime.

With built in diagnostics on the AXF and RXF models, electrode corrosion and build up can be monitored and displayed. Predictive maintenance can be put in place due to the standard feature of electrode impedance monitoring. Periodic maintenance is no longer required. Using the LCD display, the coating level of the electrodes can be monitored. When the impedance reaches third level, a warning is displayed. At level 4, an alarm can be triggered and displayed.

Dual frequency excitation

The Admag AXF dual frequency excitation has the advantages of both high and low frequency meters. Dual frequency excitation provides good zero stability and accuracy of 0,35% or 0,2% as options of reading and immunity to slurry noise. Further, the “Enhanced Dual Frequency Excitation Method” is introduced to cope with more difficult application such as high concentration slurry measurement. AXF’s new enhanced dual frequency option provides an even higher excitation frequency of 165 Hz for maximum slurry noise reduction when needed, without sacrificing zero stability.

With this feature, a stronger magnetic field is created and ensures superior signal to noise ratio. Flow data can be updated every 13 ms and improves flow measurement performance by a factor of 10 compared to standard pulsed DC type magnetic meters.

Leak-free electrodes and PFA liners

Non-retained liners (extruded liners), commonly used in conventional meters, are susceptible to failures as a result of vacuum conditions caused by pump or valve failures. Drastic temperature changes can also create pipe vacuum and cause liners to collapse. In addition, meters that have extruded liners generally have a shorter life due to the aggressiveness of the chemicals used.

Yokogawa uses an injected moulded PFA liner with a retaining grid on the Admag AXF. This retaining grid plate, used to reinforce the PFA liner, acts like rebar in concrete. This rugged construction holds the liner in place and prevents it from collapsing due to vacuum conditions. The thickness and durability provides a flow tube that is capable of handling the most severe applications.

As mentioned, the flowmeter introduces fluid adhesion diagnosis on the electrodes, which enables predictive maintenance. In addition, with the utilisation of Admag AXF’s replaceable electrode type flow tube, electrodes can easily be removed and cleaned without removing it from the piping.

Admag CA capacitance solution with mirror finished liner

In red-mud application, pregnant liquor (caustic based) quickly forms a thin, hard insulating layer on the pipe walls. This coating cannot be removed in-line by either chemical or mechanical means. The conventional electrode type magnetic flowmeter would stop operating once coated, causing downtime. The meter would have to be removed from the process line and manually cleaned.

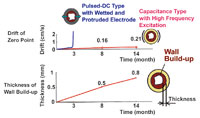

Maintenance required every 2 to 3 months could be extended to every 12 to 18 months with electrode-less Admag CA which can continue the operation even once coated. The rate of red-mud build up is well known. With this knowledge, the reduction in flow area can be calculated in the DCS and used to correct the measured volumetric flow rate as indicated in Figure 1.

Yokogawa’s Admag magnetic flowmeter series delivers fit-for-purpose solutions for difficult applications in the mining industry, providing stable and accurate measurements in severe process conditions and harsh environments.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved