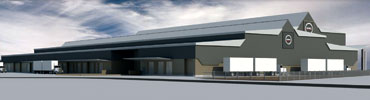

The R350-million expansion of BMG’s distribution and engineering facilities in Johannesburg is well under way. BMG Park will be renamed BMG World to reflect the company’s ability to supply integrated engineering solutions to southern African industries.

“The objective of this development programme is to centralise functional and support operations onto one site to improve supply chain processes across the Group,” says Vasu Govindasamy, BMG’s supply chain projects manager. “Through this rationalisation initiative, BMG strives to achieve cost optimisation, improve regionalised branch office support and enhance customer service capability.”

The project, due for completion in December, encompasses modifications to existing buildings and the erection of new structures.

Functional operations at BMG World will include a product warehouse and distribution centre for the entire product range and a manufacturing centre and general engineering workshop. There will also be specialist assembly and repair workshops for drives, conveyors, hydraulics and pneumatics, as well as electric motors, electronics, gaskets, lubrication systems and filtration.

BMG has invested in the latest materials handling equipment, including high bay reach trucks, to optimise volumetric efficiency. Special machinery at the new facility includes eight dock levellers that will handle approximately 120 containers a month and a regenerative load test rig.

This new load test rig will play a critical role in bringing the tangible benefits of the company’s production efficiency to South African industry. It has been developed in response to demand from local industry for absolute reliability from new gearboxes. This system uses the latest technology to transmit and apply loads of up to 30 000 Nm, enough torque to test the majority of Paramax gearboxes in BMG’s range.

BMG World will also be home to field services. BMG now has 140 mobile technicians with specialist technical skills and equipment to conduct breakdown and routine maintenance on plant. This team carries out trouble-shooting and advises on possible productivity improvements, to ensure the highest level of plant output and reliability.

Specialist services include installation, adjustment, replacement and maintenance of components, shaft and pulley alignment, balancing, condition monitoring, oil sampling and analysis and critical equipment inspections and lubrication schedules.

The upgraded premises will also include significantly expanded training facilities for the Training Academy’s practical and theoretical training. This will be open to both company employees, as well as BMG customers. The company is in the process of expanding the scope of SAQA aligned training modules and recognises the need to grow engineering skills, not only for its own succession requirements, but also for the development and sustainability of African economies.

For more information contact Vasu Govindasamy, Bearing Man Group, +27 (0)31 576 6456, [email protected], www.bmgworld.net

| Tel: | +27 11 620 1500 |

| Email: | [email protected] |

| www: | www.bmgworld.net |

| Articles: | More information and articles about Bearing Man Group t/a BMG |

© Technews Publishing (Pty) Ltd | All Rights Reserved