To achieve maintenance and reliability with compressed air, users are often drawn to the idea that a compressed air dryer is ‘the solution’. Compressed air without a dryer and filter bank will be wet, oily, contaminated and will cause hours of unnecessary and costly downtime.

What is a dryer?

A dryer is a box that contains heat exchangers, a Freon cooling system and a pair of externally mounted filters on the inlet and outlet. Its function is to reduce the incoming air temperature to 3°C. At this temperature the water and oils condenses out of the vapour to form a liquid condensate. This liquid waste is drained out of the dryer by automatic drains, and, as this waste is toxic, a proper waste separation system is required that will allow clean water into the drains and retain the oils for proper disposal.

So any dryer will do right?

No, not quite, dryers and the filters are sized for the heat load that they are required to treat. Heat load is made up of the volume of compressed air, the pressure and temperature at which it enters the dryer at, as well as the ambient air temperature compressor room the targeted dew point targeted – in this case 3°C.

The supplier’s brochure will show a number of tables that relate to the items above and it will also show how to de-rate the dryer. Failure to do this, especially in hotter areas, will lead to hours of frustration and downtime. If the tables are not shown, it is time to find a new air dryer supplier! The chances of getting a dryer to work efficiently in Africa when de-rated from flow rates obtained from product catalogues meant for the cooler northern hemisphere, is close to zero. They will either simply not work, or even worse, components will break within the dryer. That is not the desired outcome, so a general rule of thumb is the hotter the compressor room the bigger and more expensive the drier will be. The cooler the environment, the smaller the dryer will be and the price will go down proportionally.

What is the air volume?

There are three ways to establish the air volume:

1. Ask the supplier for the FAD (free air delivery) volume from the compressor at the required working pressure.

2. Measure the flow with a thermal mass meter. This will require the services of an air audit professional.

3. Calculate the air volume based on the kW rating of the air compressors main motor.

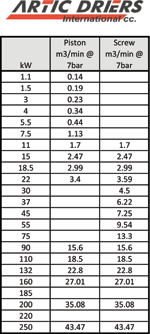

The table shows the amount of compressed air that is delivered from the two different types of compressors based on their kW ratings. It is a general guide, but will suffice in 90% of applications.

The importance of filters

The elements need changing periodically and this costs money, but the improvement in compressed air quality is immense. Filters remove the contamination generated by the compressor and released by old pipe systems. The pre-filter will remove oils and particles from the incoming air before the automatic drain inside the dryer gets jammed with this rubbish. A dryer with a jammed drain is a water generator – not a water remover!

The final filter will remove the last traces of oil and filter down to at least 0,1 micron. If necessary, for very sensitive applications, add an activated carbon filter for even finer filtration.

Filters are also sized on air flow and pressure, so read the sales literature and select the correct filter for the flow and pressure ratings.

In summary

The truth is that many companies get the de-rate selections wrong, or simply fail to apply them. Many do not know the importance of the de-rate factor, nor do they understand the consequences of not getting this right. The impact of getting it wrong is huge, and when it is wrong it’s wrong, there is no magic trick to rectify an undersized air dryer of filter. It is something the user has to get right first time, as the consequences can be time wasting and costly.

For more information contact Allen Cockfield, Artic Driers International, +27 (0)11 420 0274, [email protected], www.articdriers.co.za

| Tel: | +27 11 420 0274 |

| Email: | [email protected] |

| www: | www.articdriers.co.za |

| Articles: | More information and articles about Artic Driers International |

© Technews Publishing (Pty) Ltd | All Rights Reserved