Keeping accurate tabs on cooking oil consumption

October 2001

PLCs, DCSs & Controllers

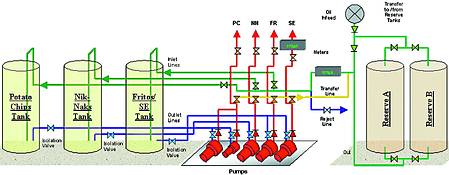

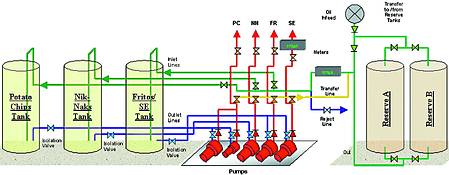

Simba Foods recently contracted Ana-Digi Systems to construct and program an intelligent PLC system to route and log the flow of cooking oil in its Parow, production facility.

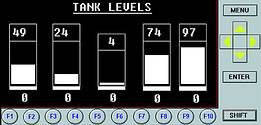

The oil for the four production lines is pumped into and stored in three main tanks and two reserve tanks. Tank levels are monitored by loadcell and ultrasonic measurement equipment, with production line routing being effected by 18 butterfly valves. Oil inflow is measured in litres via a flowmeter common to all tanks. A second flowmeter measures the consumption of oil to the soft extrusion (SE) line. By utilisation of inflow and outflow information and current tank quantities, accurate records can be kept of oil consumption on all lines. Pump and valve sequencing is selected on a LG PMU 200 HMI connected to a LG GM6 rack-mounted PLC, while tank level and mass values are retransmitted from the measurement equipment to two analog input modules on the same PLC.

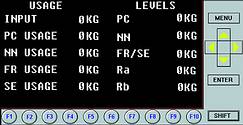

The tank content inflow and consumption values appear on the HMI enabling accurate record keeping to be realised. Value sequencing grids were set up on easily understood screens. A flow selection then automatically excludes any illegal valve or pump combination. As the sequencing is correlated with the pipeline versus product information, accurate records of individual line consumption can be interpolated.

Tank level screen

It is the intention of Simba management to tie oil consumption records to a Microsoft Excel spreadsheet at a later date. The facility is available via an OPC server or DDE link. After three months, the system has performed impeccably, so much so, that expansion of the system is being contemplated to accommodate additional storage tanks handling maize flour.

Usage screen

Abbreviations used on screens:

PC - Potato chips

NN - Nik-Naks

FR - Fritos

SE - Soft extrusion

Ra - Reserve storage tank A

Rb - Reserve storage tank B

Ana-Digi Systems

(021) 948 1452

[email protected]

www.anadigi.co.za

Further reading:

All eyes on the modern DCS platform

Schneider Electric South Africa

PLCs, DCSs & Controllers

Modernised DCS platforms are no longer confined to hardware-dependent architectures. These systems have evolved to combine the strengths of both PLCs and DCS while adding capabilities that make them more open, resilient and collaborative.

Read more...

Automation solution for waste management at incineration facility

PLCs, DCSs & Controllers

Valmet is to deliver an automation system to Seongnam City’s incineration facility currently under construction in South Korea. By leveraging intelligent automation, the plant will optimise energy production, minimise emissions and deliver efficient, consistent performance throughout its entire lifecycle.

Read more...

Valmet’s supplies DCS to Europe’s largest electric boiler plant

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system to Helen’s Hanasaari electric boiler plant and a thermal accumulator being built in Helsinki, Finland. Once completed, it will be Europe’s largest electric boiler plant.

Read more...

Technology blueprint paves way for e-methanol fuel expansion

Schneider Electric South Africa

PLCs, DCSs & Controllers

Schneider Electric has delivered the technology stack behind European Energy’s Kassø Power-to-Xfacility, the world’s first commercially viable e-methanol plant.

Read more...

PCS Global delivers turnkey MCC installation in Botswana

PCS Global

Editor's Choice PLCs, DCSs & Controllers

PCS Global is delivering a turnkey containerised MCC installation for a major copper mining operation in Northwest Botswana.

Read more...

New energy-efficient evaporation line for dissolving pulp production

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s €75 million project to convert the Biotek mill to produce dissolving pulp for the textile industry.

Read more...

Valmet modernises turbine automation

Valmet South Africa

PLCs, DCSs & Controllers

Valmet has received an order to deliver a comprehensive replacement of plant DCS and turbine control systems at Ennatuurlijk’s combined cycle power plant in the Netherlands.

Read more...

Hybrid DCS for an evolving industrial landscape

Schneider Electric South Africa

PLCs, DCSs & Controllers

Today’s industrial automation continues to evolve at a blistering speed, which means traditional DCSs have to keep up to ensure continuous integration into modern, digital infrastructure.

Read more...

IIoT controller for the field and control cabinet

ifm - South Africa

PLCs, DCSs & Controllers

The IIoT controller from ifm is a powerful, communicative and flexible PLC solution in machine and plant digitalisation.

Read more...

Bringing the benefits of Ethernet to hazardous industrial environments

ABB South Africa

PLCs, DCSs & Controllers

Christian Johansson, global product manager for ABB Process Automation explains how Ethernet-APL lets plant owners unlock more value from their process data, optimise performance and promote safer operations.

Read more...