Control in the field is a key part of process integrity. Field control keeps the process running, despite loss of visualisation, control network and controller functions. Moreover, with decentralisation of control, speed of response is improved.

Benefits:

* Improved control loop performance.

* Increased reliability and availability.

* Improved loop integrity.

* Reduced loading on DCS/PLC and network.

* Lower capital and installation costs.

* Reduced operating costs.

About Valve & Automation positioners

Valve & Automation has been providing Total Valve & Control Solutions to the chemical, refining, mining & minerals, pulp & paper, sugar, steel, power generation and other major key process industries throughout South Africa. V&A iCon offers a wide range of control valve positioners, from pneumatic and analogue devices to the most advanced smart positioners that work alongside any application in any industry. These valve positioners are certified to ATEX, FM, CSA, INMETRO, GOST or NEPSI. V&A iCon valve positioners provide solutions for HART, FF H1, Profibus PA communication, Foundation fieldbus and are SIL3 certified for applications with safety valves.

Technical challenge

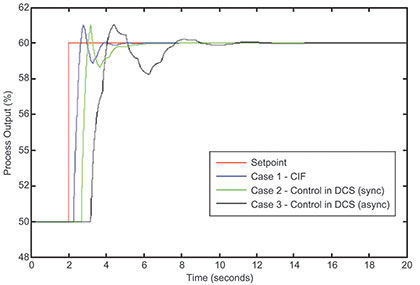

Embedded control functionality in field devices, otherwise known as field control, is one of the key factors for achieving high availability control and is a stepping stone towards single loop integrity. The premise is simple. With control at the device level, control is truly distributed, and there is truly no single point of failure in the system above the H1 level. If there is a malfunction in the HMI and a loss of visibility into the process, all other components in the system and the control loop will remain unaffected; that includes controllers, intelligent field devices, actuators, positioners, and the network.

In cases where control resides in the DCS, field level control can add another level of redundancy. Many end users already avoid unplanned downtime when field level control takes over after a failure in the system.

V&A iCon Fieldbus positioners were already able to implement ‘Control in the Field’ but in that first step of development, functionality was limited to basic function blocks (PID, AI, AO). The positioner could have controlled a local loop but with restricted capacity. The goal was to take full advantage of the Fieldbus capabilities in order to provide our end-users the most advanced Fieldbus positioner available.

V&A supply Foundation Fieldbus H1 positioners with PID, AO, two DI, DO, IS, OS, AI, MAI function blocks and LAS functionality. The Fieldbus positioner now provides state-of-the-art functionality regarding Fieldbus blocks. For instance, with the Output Selector, this positioner is now able to dispatch output to one destination or to another according to a condition value. With this complete range of function block, an enhanced ‘Control in the Field’ can be implemented. The positioner has successfully passed the latest ITK test 6.01.

Results

With its enhanced range of function blocks, the V&A iCon positioner is a powerful tool for improving the integrity and performance of the process. As a ‘Link Master’, the positioner can take over from the control system in case of failure. The increased reliability and availability of the process with ‘Control in the Field’ technology significantly reduces unplanned incidents and provides greater accuracy of control.

In addition, according to the Fieldbus Foundation, ‘Control in the Field’ has the potential to deliver a 30 percent improvement in control performance with very fast, fast, and medium-speed process dynamics. CIF can also provide up to three times higher control loop availability than a Distributed Control System (DCS). Additional benefits are:

* Reduced wiring.

* Reduced footprint.

* Significantly reduced hardware requirements in the form of I/O and controllers.

For more information contact Fred Venter, Valve & Automation, +27 (0)11 397 2833, [email protected], www.valve.co.za

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

© Technews Publishing (Pty) Ltd | All Rights Reserved