Ormen Lange is Europe’s third largest natural gas field and the largest, most demanding industrial project ever carried out in Norway. What makes Ormen Lange so challenging to exploit is its location: the ‘long worm’ lies 120 kilometres northwest of Kristiansund in the Norwegian continental shelf, where seabed depths vary between 800 and 1100 metres. Pipelines and installations had to be placed on the extremely steep and uneven area of the sea bed. In addition, the installations must withstand the exceptional currents that are characteristic of this part of the Norwegian Sea, as well as sub-zero temperatures and extreme wind and wave conditions. All these put great demands on the technology used in the project.

No platform

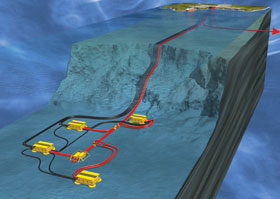

Due to the conditions, the development of Ormen Lange is different from other offshore projects: There is not a single platform on the surface of the sea above the gas field. Instead, 12 subsea wellheads at three seabed templates have been installed on the ocean floor and connected directly by two 760 mm diameter pipelines to an onshore process terminal on the Norwegian coast. There the gas is purified, dried and compressed before it is exported through the world’s longest subsea gas pipeline – Langeled pipeline – approximately 1200 kilometres to the reception centre on the east coast of the United Kingdom.

This way the Ormen Lange plant exports 70 million cubic metres of gas to the UK every day, covering 20% of its demand for natural gas, it will continue to do so for an expected 40 years. The reservoir is approximately 40 kilometres long, 8 kilometres wide, and lies about 3000 metres below sea level. Ever since gas production started in September 2007, the field has been recovered by pressure depletion only, but as production continues, natural pressure in the Ormen Lange reservoir will decline and a need for compression will arise. The customary concept today is to use a floating platform, fitted with compressors. But, the petroleum industry is now looking at new compressor technology for the Norwegian continental shelf.

New solution for compression

Shell and the other licence partners are currently investigating the possibility of implementing a subsea compressor for Ormen Lange. In order to find out whether it is technically and economically feasible to compress the gas at depths of 800 metres, they constructed a huge physical test station on the mainland. One of the major problems is that the pressure must be generated and an antifreeze added to the well stream before it enters the feed lines. Due to the low water temperatures the well stream runs a risk of forming hydrates, which can clog the pipelines. On land, gas and antifreeze have to be separated again. As the whole compressor station will operate at the seabed in 800m water depth, high reliability, low breakdown susceptibility and a low maintenance design are major requirements for the equipment. Therefore the gas and condensate pumps, which play an essential role in the process, must not only be protected from total loss by dry running or back flow, but also from wear and long-term damage caused by low load operation. This protection can be achieved by a single component – the automatic recirculation valve.

There are only a few suppliers in the world capable of designing this type of valve. The developers’ choice fell on the company which holds the original design and has the most experience – German based Schroeder Valves. Schroeder automatic recirculation valves (SSV) could provide the protection functions and meet the requirements regarding reliability and low maintenance. A rotary bypass trim design guarantees modulating and low-wear minimum flow control. The SSV has a non return function in the main pumping direction which prevents pump damage by back flow from the process line. A multi-stage pressure reduction in the secondary outlet ensures low cavitation levels, and, as an additional benefit, the valves are self actuated which means there’s no need for an actuator, auxiliary power supply or any kind of control devices. The valves, like all other equipment, are soon to be in operation at the test station. Once testing has been completed, the partners at Ormen Lange will decide whether to install the new technology on the seabed above the reservoir.

For more information contact Fred Venter, Valve & Automation, +27 (0)11 397 2833, [email protected], www.valve.co.za

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved