In the process industry there is a growing interest in wireless data communication, not just for standard connections, but for applications where wires cause obstruction. BASF, one of the world’s leading chemical companies, has experience with a number of wireless applications.

Catalyst production at the De Meern plant

When catalysts are being produced the product goes through a number of steps. One of these is the drying process that takes place in a large vacuum dryer. This is in the form of two cones connected at the base, each with a diameter of approximately two metres. The product, a powder, is fed in from the top through the tip of the cone in which a manual valve is mounted. On the other side, the tip of the other cone, there is an access point for taking samples.

The vessel is suspended from two points on each side of the connecting surface. It revolves around these points, ensuring that the product is mixed well with a special liquid injected through one of the rotation points. This liquid forms a coating around the powder grains. The product must then be thoroughly vacuum-dried before the final product is tipped out of the vessel via the same valve.

Samples have to be taken regularly during the process to assess the dryness of the product. For this purpose the rotating drum is stopped and the operator takes a sample through the special access valve which is then analysed in the laboratory. This operation takes between 30 to 45 minutes and when the product is sufficiently dry, the process can be stopped and the product tipped out. The total drying process takes approximately eight hours.

Ferry Stofberg BASF: “We went in search of alternatives so that we could dispense with the time consuming sampling process and free-up the operators. On the Endress+Hauser stand at a trade fair, we saw a demonstration of a wireless set-up for measuring temperature. The system used standard transmitters and a module with an antenna was used to transmit the data to a host by means of WirelessHART. For us, this seemed an excellent solution.”

System overview

After the technical solution had been delivered by Endress+Hauser, the BASF engineers looked for additional possibilities. Temperature is the primary variable for determining the moisture content of the product, but in addition, the pressure in the drum is of interest. Therefore two transmitters were fitted, one for pressure and one for temperature.

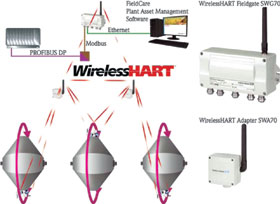

Another criterion was straightforward integration into the existing system. Control is via Siemens PLCs and Profibus with FieldCare software used for maintenance. The gateway has a 24 V feed and two outputs, Modbus and Ethernet. The Modbus signal was converted to Profibus DP for communication with a PLC. Endress+Hauser provided the essential programming with connection to FieldCare via Ethernet.

The WirelessHART adaptors, which also supply power, are mounted directly on the transmitters and transmit the HART information from the instruments on the continuously rotating drum to the gateway. Experiments are still ongoing, but have already revealed the P-transmitter uses more energy than the T-transmitter. Longer intervals (e.g. two minutes) between measurements have produced an excellent saving. Another possibility is to switch the transmitter on and off when required using WirelessHART commands.

The expectation is that, before long, the process can be fully automated. This would result in an impressive time saving and improvement in product quality. At that point, two other drums will also be fitted with the new wireless measuring solution from Endress+Hauser.

For more information contact Hennie Blignaut, Endress+Hauser, +27 (0)11 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved