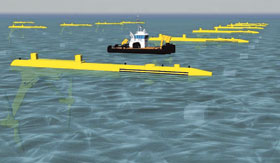

Utilising the tidal power of the North Sea as a source of alternative energy is attracting increasing attention from academia and industry. Scottish company, Scotrenewables Tidal Power, has developed an innovative tidal current turbine that is specially designed for the demanding conditions in the North Sea. Unlike conventional systems, it requires no elaborate structural anchoring on the seabed as it floats on the water, all control functions are handled by an integrated PC and EtherCAT-based control platform. The SR250’s innovative system leads to significant cost reduction, meaning tidal power could soon start playing a more important role for renewable energy.

Robust, innovative design

A system that is to function under the harsh conditions in the North Sea must be robust and highly reliable with minimum maintenance requirements. A 250 kW prototype of the SR250 is currently undergoing a thorough, two-year test programme by the European Marine Energy Centre (EMEC) at the Fall of Warness tidal power test centre off the Orkney islands.

Two counter-rotating rotors pick up kinetic energy from the tidal current, which is converted to electrical energy by a generator and brought ashore through a cable buried in the sea bed. The tidal turbine essentially consists of a cylindrical tube to which the rotors are attached parallel to the horizontal axis via folding struts. The struts enable the tidal turbine to assume two positions: in operating mode the rotors are extended under water and in transport and survival mode, which the plant assumes in heavy seas, the rotors are retracted in order to protect them from excessive loads.

Low operating costs ensure viability in a competitive industry

The main aims of Scotrenewables in the development of the tidal turbine were simple installation and operation, ease of access, straightforward maintenance and robustness. The company is convinced that running costs are the main factor for the competitiveness of tidal power compared with other renewable energy sources. Conventional tidal power plants generally have a rigid structure with associated foundations and require costly special equipment and transportation facilities for installation and maintenance on the high seas. In contrast, the floating tidal turbine can be installed with a general-purpose workboat making the process much cheaper. Once operational, the plant can be towed quickly and cost-effectively to the operating site or back to port for maintenance.

Integrated PC-based control

The SR250 uses a fully integrated Beckhoff control platform, including an Industrial PC, EtherCAT I/Os, in protection class IP67, and the TwinCAT automation software. It controls all operating functions of the plant including movement of the turbine arms, data-logging and operational and remote monitoring. System communication is based on an EtherCAT ring topology, which offers wiring redundancy and ensures that the system remains operational even in the event of a broken wire. This design ensures fast configuration during which only a few low-voltage cables have to be connected. The system controls all moving parts, including the hydraulic system, and communicates with external devices such as variable-speed drives. All monitoring tasks are handled via the TwinCAT HMI tool that requires no drivers or other communication protocols, and in which the variables are addressed locally in the same software as the programming logic.

Alan Smith, Beckhoff regional manager for Scotland says, “This is a particularly innovative and demanding project. Accordingly, there were stringent requirements for the control components with regard to robustness and availability. For this reason Scotrenewables demanded absolute reliability and high MTBF values. The openness of our integrated control solution was an important prerequisite for speeding up the engineering without the risk of interoperability issues. The EtherCAT platform is ideal for research and development projects such as the SR250, since it enables a modular approach.”

Angel Rua, development engineer at Scotrenewables concurs: “The design concept of the SR250 enables various tests to be carried out, including towing tests. We can use these to simulate tides in a controlled manner and check all on-board systems. The test under full power was very successful and demonstrated that our floating turbine can produce energy reliably and efficiently and achieve its rated output of 250 kW. The tests relating to in-situ power generation with grid connection were also very successful.”

The result is that Scotrenewables is now on schedule with the development of its next-generation 2 MW turbine for commercial application. The SR2000 is designed to achieve a rated output of 2 MW at a flow rate of 3 m/s, which means it would be one of the most high-powered tidal turbines in the world, perhaps even the most powerful to date.

For more information contact Kenneth McPherson, Beckhoff Automation, +27 (0)11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved