Pumps running dry can cause considerable problems, something operating personnel of LPG plants and oil depots know all too well. Sometimes the problems are only minor, such as unusual noise and vibration. Sometimes they are more serious and may entail operating downtime or even considerable damage. These problems occur mainly during start-up or pump restart, and they often happen despite staff being present on-site.

In processing plants, such pumps are usually remote controlled or are started via central plant control. This means it is usually not possible to check whether pumps have been adequately gas vented or filled. When pumping fluids near their boiling point, or liquid gases at boiling point, even a slight increase in the temperature of an idle pump can cause the liquid phase to be converted to gas. This volume of gas then presses the liquid from the pump towards the suction pipe, with the result that the pump is entirely or partially filled with gas. ‘Gassing-up’ is caused by two factors: the effect of ambient heat and the effect of the residual heat within the pump immediately after the unit has been switched off. Depending on the design of the pump, this will either cause it to run dry completely or will fill it with gas to such an extent that the impellers cannot build any pump pressure during re-start. The pump therefore runs dry, which can lead to pump wreckage and damage to plant in the vicinity.

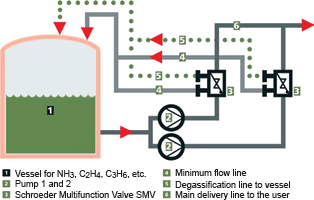

Automatic gas venting

The automatic gas-venting system integrated into the Schroeder SMV multifunctional valve continuously ensures automatic gas venting of idle or back-up pumps, ensuring they always remain filled with the transport medium. The valve is installed near the pressure connection of the centrifugal pump in an elevated position, which ensures there is a geodesic high point below the return cone on the pressure side of the pump in the direction of the main flow. When the pump is idle, gas collects in the vicinity of this high point. The gas-venting function of the multifunctional valve is automatically kept open when the pump is idle. This ensures continuous gas venting while the pump itself always remains completely filled with the transport medium.

In case of liquid gas used at very low temperatures, the SMV ensures that the pump is constantly kept ‘chilled’, ready for risk-free, safe starting or restarting. Immediately after start-up, the pump generates the required differential pressure and the automatic gas-venting system of the SMV valve seals off the gas-venting pipe. Once the pump is switched off, the drop in differential pressure will automatically cause the gas-venting system to open, so that any gas caused for example by residual heat from the pump is immediately dissipated. The pump remains filled with liquid until it is next switched on or automatically restarts. A further benefit of the SMV valve is that the pump and motor capacity can be significantly downsized, which in turn has a positive effect on the energy balance and plant costs.

Applications

The characteristics described make the Schroeder SMV multifunctional valve a pump protection system whose use is especially necessitated when processing highly technical liquid gases, particularly when dealing with tank storage and loading of liquid gases at low temperatures. In addition, the valve is especially suitable for all pump systems lifting liquids close to boiling point, for pumping two-phase mixtures and gaseous media and for pumps equipped with gas injection using modern sealing systems or similar devices. In this context the Schroeder multifunctional valve prevents especially canned pumps and magnetic pumps from running dry.

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved