Real-time online thermographic analysis

June 2012

Temperature Measurement

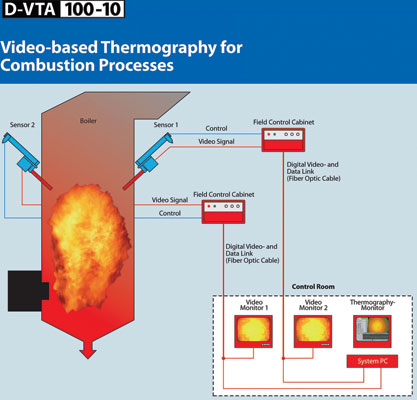

The video based D-VTA 100-10 thermography system from Durag supplies online information directly from the combustion chamber to assist the operator in adjusting the complete combustion process optimally. The system provides a real-time video image as well as a real-time online thermographic analysis of the temperature distribution inside the combustion chamber.

The thermographic system is an optical pyrometer based on advanced video data processing technology. A high quality picture with a wide angle of view and a small sensor diameter are obtained with a boroscope lens. The CCD camera is mounted in the cold part of the lance, thus allowing sensitive equipment to be mounted outside the combustion chamber for continuous use at high temperatures. A sapphire lens and air flushing are used to protect the boroscope tip from slag and ash particles.

In addition to the video image, the system allows thermal analysis of the spatial temperature distribution inside the combustion chamber. It can determine the temperature within freely definable areas along the region of interest (ROI) and line of interest (LOI). The system is also capable of continuous parallel temperature analysis in all ROIs with continuous display of the absolute temperature on the screen. Other capabilities include the ability to perform continuous temperature analysis along all LOIs with continuous display of the absolute temperature profile through the combustion chamber, and the detection of the actual thermal position of the combustion zone.

To guarantee the largest and unobstructed observation range, the sensors, along with their optical systems, are directly moved into the combustion chamber. To withstand high temperatures between 700°C and 1600°C (typical for these furnaces) the sensors are air or water cooled. All parts which may be affected by the flue gases are made of special stainless steel to cope with the chemical reactions and high temperatures of the flue gas.

For more information contact Colwyn Savings, OEN Enterprises, +27 (0)11 675 4447, [email protected], www.oenenterprises.co.za

Further reading:

Infrared solutions for glass manufacturing challenges

Temperature Measurement

In the glass industry, infrared temperature monitoring is crucial for maintaining product quality and process efficiency. Instrotech has infrared sensors and cameras which provide non-contact temperature measurements, making them ideal for these high-temperature environments.

Read more...

Intelligent process stabilisation in injection moulding

Temperature Measurement

A new benchmark in precision temperature control for plastics processing is being set by technotrans.

Read more...

New temperature transmitters with Profibus connectivity

Temperature Measurement

Siemens is enhancing its temperature measuring device portfolio with the transmitter duo, Sitrans TH420 PA and Sitrans TF420 PA. Both devices feature Profibus connectivity, advanced safety functions and expedited commissioning all in one unit.

Read more...

Enhancing industrial efficiency through advanced temperature control

Iritron

Temperature Measurement

Iritron has been offering modular smart thyristor drives to the local and international mining, minerals and metals market, including the latest new leading innovations in temperature control technology. These drives combined with advanced proportional-integral-derivative (PID) control will change the way large industries manage their heating processes, reducing costs and extending equipment lifespan.

Read more...

Non-contact infrared thermometer

Temperature Measurement

AMETEK LAND has developed a new non-contact infrared thermometer for precise measurement and control during deposition processes in optical fibre manufacturing.

Read more...

High-precision fill quantity control in food supplement production

Temperature Measurement

Vital Products was looking for a precise and efficient solution to check the weight and ensure the completeness of its products. Minebea Intec, a specialist in industrial weighing and inspection technologies, was able to provide a solution.

Read more...

The critical role of temperature measurement in flame hardening

Instrotech

Temperature Measurement

Flame hardening is a heat treatment process widely used on parts made from mild steels, alloy steels, medium carbon steels and cast iron. Accurate temperature measurement is not just important, but critical for the success of flame hardening.

Read more...

Noncontact infrared temperature control in aluminium rolling process

Instrotech

Temperature Measurement

The aluminium rolling process is critical to the aluminium manufacturing industry, where precise temperature measurement is essential for ensuring high-quality product output and protecting equipment. The Optris long-wavelength camera can accurately measure strip temperatures in cold rolling and coiling applications.

Read more...

Where simplicity meets reliability

Endress+Hauser South Africa

Temperature Measurement

The new iTEMP TMT31 temperature transmitter from Endress+Hauser combines simplified selection, ordering, installation and operation with the highest reliability and long-term stability in one product.

Read more...

Automating car window defrosters

Temperature Measurement

Window defrosters are vital features in vehicles, particularly in colder climates. The automotive manufacturer seeks an efficient solution to quickly and precisely measure the temperature of the windows, ensuring that the connections, installed cables and wires work correctly and have no defects before the vehicle’s final release.

Read more...