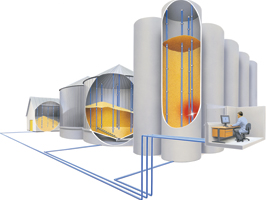

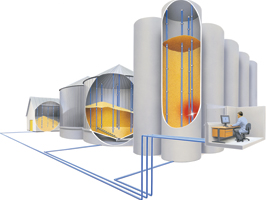

Ronin's grain temperature control solution

June 2012

Temperature Measurement

Grain can be stored in many ways, for example in silos or in flat stores. It is a common belief that the only threat to this stored grain is insects, impurities and rodents. This is only partly true because the real threat to stored grain are factors like moisture, ambient temperature, humidity, storage time and the grain temperature. If these parameters are not in balance, a reduction of the grain quality could occur and may result in severe damage to the crop.

An essential factor for grain quality is the balance between water content and temperature. If one of these factors is too high the grain might start to ‘sweat’. During sweating the grain will emit dry matter and water (loss of weight). In case the process is not stopped, the conditions in the silo or flat store will provide optimum condition for micro organisms, insects and other impurities. This could result in a self-perpetuating process destroying the grain even faster. With Cimbria’s temperature monitoring system, the operator is able to act in time to prevent possible negative developments in the stored grain. Problems with the stored grain may be solved either by moving, drying or ventilating it.

The Unitest UT 3000W Software, which is the front end of the Cimbria system, is used to measure temperature in grain silo bins to ensure safe storage. The software works in the Windows environment. All systems and process data are saved in a database configured to each individual storage plant. The database structure makes it easy to organise, operate and maintain the data as well as exchange with other computers using dynamic data exchange. A special version of the software contains an aeration control system which works in both manual and automatic modes. The system is available in two versions: temperature monitoring and temperature monitoring and aeration control.

For more information contact Edward Herridge, Ronin Grain Management Solutions, +27 (0)11 608 3666, [email protected], www.roningms.com

Further reading:

Infrared solutions for glass manufacturing challenges

Temperature Measurement

In the glass industry, infrared temperature monitoring is crucial for maintaining product quality and process efficiency. Instrotech has infrared sensors and cameras which provide non-contact temperature measurements, making them ideal for these high-temperature environments.

Read more...

Intelligent process stabilisation in injection moulding

Temperature Measurement

A new benchmark in precision temperature control for plastics processing is being set by technotrans.

Read more...

New temperature transmitters with Profibus connectivity

Temperature Measurement

Siemens is enhancing its temperature measuring device portfolio with the transmitter duo, Sitrans TH420 PA and Sitrans TF420 PA. Both devices feature Profibus connectivity, advanced safety functions and expedited commissioning all in one unit.

Read more...

Enhancing industrial efficiency through advanced temperature control

Iritron

Temperature Measurement

Iritron has been offering modular smart thyristor drives to the local and international mining, minerals and metals market, including the latest new leading innovations in temperature control technology. These drives combined with advanced proportional-integral-derivative (PID) control will change the way large industries manage their heating processes, reducing costs and extending equipment lifespan.

Read more...

Non-contact infrared thermometer

Temperature Measurement

AMETEK LAND has developed a new non-contact infrared thermometer for precise measurement and control during deposition processes in optical fibre manufacturing.

Read more...

High-precision fill quantity control in food supplement production

Temperature Measurement

Vital Products was looking for a precise and efficient solution to check the weight and ensure the completeness of its products. Minebea Intec, a specialist in industrial weighing and inspection technologies, was able to provide a solution.

Read more...

The critical role of temperature measurement in flame hardening

Instrotech

Temperature Measurement

Flame hardening is a heat treatment process widely used on parts made from mild steels, alloy steels, medium carbon steels and cast iron. Accurate temperature measurement is not just important, but critical for the success of flame hardening.

Read more...

Noncontact infrared temperature control in aluminium rolling process

Instrotech

Temperature Measurement

The aluminium rolling process is critical to the aluminium manufacturing industry, where precise temperature measurement is essential for ensuring high-quality product output and protecting equipment. The Optris long-wavelength camera can accurately measure strip temperatures in cold rolling and coiling applications.

Read more...

Where simplicity meets reliability

Endress+Hauser South Africa

Temperature Measurement

The new iTEMP TMT31 temperature transmitter from Endress+Hauser combines simplified selection, ordering, installation and operation with the highest reliability and long-term stability in one product.

Read more...

Automating car window defrosters

Temperature Measurement

Window defrosters are vital features in vehicles, particularly in colder climates. The automotive manufacturer seeks an efficient solution to quickly and precisely measure the temperature of the windows, ensuring that the connections, installed cables and wires work correctly and have no defects before the vehicle’s final release.

Read more...