High-current hermetically sealed proximity sensors

June 2001

Sensors & Transducers

By applying the economic advantages offered by the National Electrical Code and by utilisation of hermetically sealed high-current Magnum sensors, the AccuTrak 9000 merges technology with economy. Cost saving benefits are realised by the consolidation of components and the complete elimination of hazardous location seal fittings, wiring, conduit and their associated labour costs.

The Magnum proximity sensor was designed in response to customers' needs. The main requirement for any product in a process plant is reliability. The Magnum sensor is warranted to perform as specified for a full five years.

Corrosion resistance

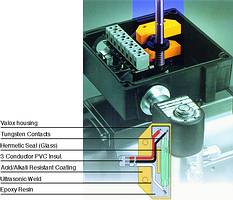

The highly corrosion-resistant tungsten contacts are hermetically sealed in an inert atmosphere to protect them from dust, oxidation or external corrosion. The entire sealed unit is then encapsulated in a plastic coating to cushion the sensor in case of shock or vibration. After encapsulation, the sensor is encased in a flame-retardant high-impact thermoplastic enclosure and then re-encapsulated in a premium grade polymer impervious to moisture, chemicals and solvents.

The Magnum sensor was developed specifically for valve monitoring applications. The Form C, SPDT contacts are manufactured from solid pieces of pure tungsten. Since tungsten has the highest melting point of all metals plus excellent electrical conductivity characteristics, the proximity sensor is capable of handling 3 A (switching) at 120 V a.c. and 2 A (switching) at 24 V d.c. The sensor is UL listed and CSA recognised.

Field reliability

The industrial environment requires products that function reliably and safely. By evaluating customers' needs, conducting field tests to confirm that evaluation and then working with design engineers to provide innovative and cost-effective solutions to those needs, the Magnum proximity sensor was conceived. Technology was borrowed from pacemakers, sensors that monitor the flaps on jumbo jets and the high-current switching capability required for large halogen underwater flashlights.

Valve & Automation

(011) 397 2833

(031) 579 2593

(035) 751 1458

[email protected]

www.valve.co.za

Further reading:

Precision sensing for water treatment

ifm - South Africa

Sensors & Transducers

ifm electronic has introduced two next-generation sensors designed for South Africa’s bulk and wastewater sector, engineered to withstand harsh environments and deliver long-term reliability.

Read more...

The next generation of inductive scanning encoder solutions

ATI Systems

Editor's Choice Sensors & Transducers

With the launch of the ECI 1122 and EQI 1134 rotary encoders, positioning specialist, HEIDENHAIN has introduced a new benchmark in inductive scanning technology that raises the bar for motion control and precision automation.

Read more...

Next-generation condition monitoring

Sensors & Transducers

The next generation Sitrans MS200 multisensor from Siemens is setting new standards in condition monitoring.

Read more...

Telco sensors for blocked/empty chute detection

Sensors & Transducers

Telco sensors overcome the problems of contaminated environments through powerful high-performance infrared sensors that ensure penetration of harsh pollution and guarantee reliable detectio

Read more...

Cleaning solutions for optical sensors

Endress+Hauser South Africa

Sensors & Transducers

Achieving accurate and continuous process visibility requires reliable sensor performance, even in challenging media. Endress+Hauser’s CYR51 mechanical cleaning unit addresses these challenges by providing stable, automated cleaning of turbidity and UV-Vis absorption sensors.

Read more...

Next-generation gas meter module

Sensors & Transducers

Sensirion has launched its new gas meter module combining a low-power consumption mode, future-ready compatibility and seamless integration, all within the same compact form factor.

Read more...

Adjustable proximity sensor with five metre range

Gail Norton Instrumentation

Sensors & Transducers

The Telco line of photo-electric eyes have the accuracy and reliability you need.

Read more...

Food safety – a matter of weight

Sensors & Transducers

Weighing systems play a key role in ensuring product quality in food production, complying with legal requirements and avoiding product recalls. The Minebea Intec MiNexx portfolio has been specially developed to meet these requirements.

Read more...

Telco sensors in the paper and pulp industry

Gail Norton Instrumentation

Sensors & Transducers

The paper and pulp industry poses a major problem for most photoelectric sensors. Telco Sensors has overcome this with its powerful and high-performance photoelectric sensors, ensuring penetration of thick and harsh pollution while guaranteeing reliable detection.

Read more...

Leaders in sensor technology

Gail Norton Instrumentation

Sensors & Transducers

A new addition to the Telco Sensors range is the adjustable Proximity sensor, with a range up to 5 metres.

Read more...