Reviewer details

Name: Tim Spandiel

Position/Designation: Project Manager: Base Metals Refinerey

Company: Impala Platinum Refineries

Tel: (011) 360 3130

e-mail: [email protected]

Product details

Vendor: Xycom SA/Industrial Systems Integrators

Product name and version: Citect Version 5.30

Tel: (011) 462 6671/(011) 704 3080

e-mail: [email protected]

General

Q: What industry (eg mining, food and beverage, automotive etc) is the scada being applied in?

A: Base metals refining.

Q: Who did the system integration?

A: System integration was a joint venture between Impala and ISI. A dedicated team of three instrumentation technicians was selected. ISI provided the menu system, symbols, face plates, etc.

Q: How is the after-sales support handled (eg remote-dial-up, e-mail, Internet access etc)?

A: A remote dail-up was used initially while the system was being set up. This was changed to personal visits when the system went live.

Q: What sort of licensing agreement is used on this particular system? Does one licence cover all modules, or can the user only buy those modules that he wishes to use?

A: The licensing options are: I/O server, display client and manager nodes. The display client and manager nodes can be fixed or floating. Impala has purchased a combination of licences. All the licences have a specific I/O count.

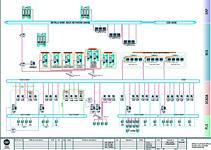

System architecture

Q: How many tag points/I/O does the installation have? Analog? Digital? Maximum possible?

A: We purchased two 15 000 I/O alarm/report/trend/FTP servers and six 5000 I/O servers. Maximum is unlimited.

Q: What operating system is the scada running on (eg Windows NT, Unix etc)?

A: Windows NT is currently used. Impala plans to upgrade to Windows 2000 during the next year. The Citect Scada system is running successfully on Windows 2000 elsewhere.

Q: What impressed you most about the architecture? Open standards, wide range of drivers, the ability to upgrade, etc? Please elaborate.

A: Citect supports a very comprehensive range of drivers. Our initial purchasing decision was based on the fact that it could interface with our 20-year old TI PM550 PLCs. Citect adheres to open standards. It is fairly easy to upgrade to the next version.

Q: Is the system integrated onto an intranet or the Internet? If so, does the configuration allow simple remote monitoring, or is it configured to allow full remote control? If not, what level of intranet/Internet control does the scada allow for future use?

A: Yes, the system has been integrated onto an intranet for the past 18 months. Remote monitoring via the intranet/Internet is done via Citect Internet Display Clients (IDCs). The BMR site can be monitored from Impala Head Office in Houghton. Remote monitoring and full remote control is possible, but Impala has opted for the remote monitoring function only. To change from the one to the other only involves the changing of the protection keys on the two global alarm, report and trend (ART) servers.

Q: What sort of redundancy is built into the system?

A: All the servers have been setup in redundant mode, ie for all three primary I/O servers there are three back-up I/O servers. All six are online at a time to spread the load. As soon as a primary server falls, the specified back-up server takes over full control. The Global ART servers are also set-up for redundancy. A remote user can log into either ART server.

Graphics

Q: Describe the graphics development process - eg did you use standard library images, or did you have to draw images from scratch?

A: A graphic artist, employed by ISI, compiled a library of symbols that were used to populate the scada mimic pages. A lot of time and money were saved because the standard symbols were re-used throughout the plant.

Q: Did you use any 'special' images (eg embedded video clips, photographs, 3D images etc)?

A: Photographs are available on certain mimics. An aerial photograph is used for the main overview/navigation page.

Compatibility

Q: Did you run the scada in conjunction with any third-party application software? Describe.

A: The scada information is summarised in an SQL 7 database using the Citect Plant2SQL package.

Q: Does the scada allow for the user to create scripts to perform specific tasks? Describe any specific scripts that were written for this project.

A: The scada allows the user to do this in 'Cicode'. An example is our customised menu system.

Management reporting

Q: Is a trending and historical data reporting system included? Please elaborate.

A: Trends and the reporting of historical data are standard functions of the scada system. Every user can configure his/her own trends.

Q: Is a management reporting system included in the package?

A: Management reporting is done from the SQL 7 database. Standard reports are being developed in Crystal Reports. Reporting is done via the intranet. Process controllers also have access to the reports via the Active-X embedding of the intranet in the scada system. Reports can also be generated in the Excel client that is provided with the Plant2SQL package.

Q: Is the system integrated into a manufacturing execution system?

A: No.

Q: Is the scada system integrated into a management reporting or control system (eg SAP, Baan)?

A: Impala uses the Protean ERP system. The scada system will be integrated with the Protean system during the next six months.

Q: Who integrated the scada into the MES and/or ERP?

A: EDS/Solit have implemented Impala's two Protean systems.

Q: Describe the integration process.

A: The integration process is in the planning phase, but should be straight forward via the SQL link that already exists.

Q: Was any additional software development needed? Please elaborate.

A: Not applicable at this stage.

Conclusion

Q: What impressed you the most about the system?

A: Redundancy.

Q: What was the predominant feature (or features) that made you decide to employ this scada, rather than another (ie ease of use, support from the vendor, upgrade path, redundancy features etc)?

A: As mentioned earlier, Citect was the only Scada system that had a driver for the TI PM550 PLCs and ISI could demonstrate this in a running facility.

© Technews Publishing (Pty) Ltd | All Rights Reserved