Bringing the shopfloor to management's door

Jan 2000

PLCs, DCSs & Controllers

Richard Pople -

"Communicating from the plant floor right up to the Ethernet is definitely new for us. The concept is 'old', but everybody would like this type of technology."

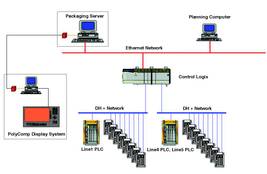

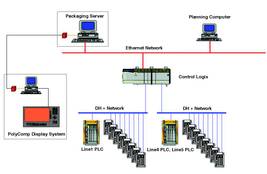

When South African Breweries (SAB), one of the world's five largest brewers, needed a way to communicate realtime changes in production to both the shopfloor and management at its Rosslyn Brewery, it asked Rockwell Automation to provide a solution. A combination of Rockwell Automation hardware and software products was installed.

Allen-Bradley equipment in the form of PLC5s and DH+ networks already existed in the plant's packaging hall. So Rockwell Automation had to find a way to incorporate the existing equipment, combine the various plant networks and make sure plant data was accessible from any level.

SAB, with the help of Rockwell Automation engineers, installed a ControlLogix Gateway that connects the DH+ networks to the Ethernet TCP/IP plant-wide network and onto the packaging server. "Previously we had something like six DH+ networks and we had to restructure our whole network so that we could take the information up to the Ethernet. That is why we used the ControlLogix Gateway," said an SAB Rosslyn spokesperson.

The Ethernet module connects to the SAB office network, allowing management to see the information from their offices and, in the future, on the company's intranet. "The line manager and the packaging manager can go into the new system from the PCs at their desks and see what is happening now and we have the option of putting information on the Beernet (SAB's term) for its intranet."

Also residing on the Ethernet is the packaging server, a Windows NT computer featuring a Microsoft SQL (MSSQL) database for data retrieval and storage. Data is passed from the PLC5s on the DH+ networks via the ControlLogix Gateway and onto the Ethernet to the packaging server. From here the data is sent to the PolyComp display unit. "The operator now has a physical picture of what has been done in the past eight hours, like V profile, volume and efficiency trends and line comparisons. He can also see the current production, if volume is being increased and if the plant is meeting its targets," said the SAB spokesperson.

RSLinx presents the data contained in the two PLC5s to the RSSQL software via DDE. RSSQL then manages the data into the MSSQL. From here a Visual Basic-developed application, from Delta Projects, configures graph displays and sends them to the PolyComp. The Ethernet connection also allows for planning personnel to enter production line target values into the MSSQL data tables. "Communicating from the plant floor right up to the Ethernet is definitely new for us. The concept is 'old', but everybody would like this type of technology."

Rockwell Automation's Global Technical Services provided dedicated support and worked in conjunction with SAB to help with this installation, the first ControlLogix and RSSQL system in South Africa.

Rockwell Automation

(011) 654 9700

Further reading:

All eyes on the modern DCS platform

Schneider Electric South Africa

PLCs, DCSs & Controllers

Modernised DCS platforms are no longer confined to hardware-dependent architectures. These systems have evolved to combine the strengths of both PLCs and DCS while adding capabilities that make them more open, resilient and collaborative.

Read more...

Automation solution for waste management at incineration facility

PLCs, DCSs & Controllers

Valmet is to deliver an automation system to Seongnam City’s incineration facility currently under construction in South Korea. By leveraging intelligent automation, the plant will optimise energy production, minimise emissions and deliver efficient, consistent performance throughout its entire lifecycle.

Read more...

Valmet’s supplies DCS to Europe’s largest electric boiler plant

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system to Helen’s Hanasaari electric boiler plant and a thermal accumulator being built in Helsinki, Finland. Once completed, it will be Europe’s largest electric boiler plant.

Read more...

Technology blueprint paves way for e-methanol fuel expansion

Schneider Electric South Africa

PLCs, DCSs & Controllers

Schneider Electric has delivered the technology stack behind European Energy’s Kassø Power-to-Xfacility, the world’s first commercially viable e-methanol plant.

Read more...

PCS Global delivers turnkey MCC installation in Botswana

PCS Global

Editor's Choice PLCs, DCSs & Controllers

PCS Global is delivering a turnkey containerised MCC installation for a major copper mining operation in Northwest Botswana.

Read more...

New energy-efficient evaporation line for dissolving pulp production

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s €75 million project to convert the Biotek mill to produce dissolving pulp for the textile industry.

Read more...

Valmet modernises turbine automation

Valmet South Africa

PLCs, DCSs & Controllers

Valmet has received an order to deliver a comprehensive replacement of plant DCS and turbine control systems at Ennatuurlijk’s combined cycle power plant in the Netherlands.

Read more...

Hybrid DCS for an evolving industrial landscape

Schneider Electric South Africa

PLCs, DCSs & Controllers

Today’s industrial automation continues to evolve at a blistering speed, which means traditional DCSs have to keep up to ensure continuous integration into modern, digital infrastructure.

Read more...

IIoT controller for the field and control cabinet

ifm - South Africa

PLCs, DCSs & Controllers

The IIoT controller from ifm is a powerful, communicative and flexible PLC solution in machine and plant digitalisation.

Read more...

Bringing the benefits of Ethernet to hazardous industrial environments

ABB South Africa

PLCs, DCSs & Controllers

Christian Johansson, global product manager for ABB Process Automation explains how Ethernet-APL lets plant owners unlock more value from their process data, optimise performance and promote safer operations.

Read more...