Westlock has merged absolute encoder sensing technology with loop-powered analog transmission to create the Spectrum DT full-range position monitor. The communication mode continues to be the standard 4-20 mA analog signal while actual sensing is achieved by a true digital sensor.

Key performance benefits include:

* Reference accuracy is three times that of traditional potentiometric analog sensors.

* Shifts due to environmental effects such as temperature are improved by a factor of three or more compared with traditional analog sensors.

* Greater repeatability and accuracy that digital control systems brought to the control room have now been extended into process measurement in the field.

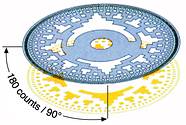

True digital position sensing

An absolute encoder is a position verification device which provides position information for each shaft location. The digital code is unique to each location. In absolute encoders, there are several concentric tracks, each with an independent light source. As light passes through a slot, a high state called 'true 1' is created. When light does not pass, a low state known as 'false 0' is created. Shaft position is identified by the pattern of 1s and 0s.

Loop-powered 4-20 mA transmission

The 4-20 mA analog signal, which has long been a useful method of interfacing sensors to remote computers, is the main standard for data transmission of the Spectrum DT. The transmitter derives its operating power from the 4-20 mA loop itself, with no need for an external power connection. This is a high-level signal not easily affected by outside noise. In addition to the advantages of standardisation, reduced field wiring costs and immunity from most electrical noise, the 4-20 mA transmitter offers these benefits:

* Any number of signal receivers can be series-connected into the signal circuit without upsetting calibration.

* Multiple transmitters may share the same power supply.

* A 4-20 mA signal is a 'live zero' signal, which distinguishes a process condition (4 mA) from an open circuit condition (0 mA).

* No position loss on power down.

* Operates in electrically noisy environments.

Operating description

The shaft encoder is an 8 bit device, utilising grey code parallel outputs. Grey to binary conversion takes place before further signal processing. Data corresponding to shaft position is latched, and fed to a high quality digital to analog converter, with timing synchronised to encoder LED excitation. A precision, low drift voltage reference is utilised for the D/A converter DC source, as it is for the scaling and live zero circuitry which follows. Voltage to current conversion develops the true current sink output characteristic provided by the transmitter. Current sampling and feedback assure that a current which is truly representative of shaft position is generated.

The internal power supply is derived in total from the 4-20 mA signal loop. Stored energy from that power supply is delivered to the encoder LEDs for excitation on a pulsed basis for a period of several milliseconds approximately once each second. In this manner, LED current excitation requirements in excess of 100 mA can readily be met despite the constraints imposed by two-wire current loop operation. Operation of the data latch and D/A converter, as mentioned above, is synchronised to LED excitation.

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved