Keywords: [active RFID, blind area, last mile, mining]

An active RFID tag is an electronic device that continually transmits information on a pre-set RF signal over a certain range. The tag comprises a microprocessor, transmitter, battery, antenna and firmware.

Abstract

This paper introduces active RFID technology: its principles of operation and capabilities. Readers of this paper can gain a proper understanding of the technology so that they can make informed decisions on its application in their sphere of influence.

Like all new technologies when first introduced, RFID has been associated with successful applications and with less successful projects. In some cases suppliers have overpromised and under-delivered for a variety of reasons.

Introduction

Active RFID technology is well suited to the mining industry, both on the surface and underground. The technology has been extensively tested, and has proved to be:

* Effective in its operation.

* Efficient in achieving the required results.

* Reliable in operation.

* Robust enough to withstand harsh and aggressive environments.

* Very affordable to deploy with a virtually zero cost of ownership.

Potential applications for active RFID cover a wide spectrum as one can tag any asset in this way: Typical applications include:

* Personnel safety.

* Equipment inventory.

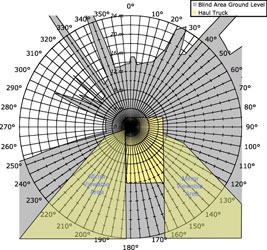

* Monitoring and control of vehicles.

Active RFID provides a platform for the active and dynamic generation of realtime data, which can provide management information to inform operations. This eliminates the need for making operational assumptions when:

* Making production for casts.

* Trying to determine the approximate position of missing personnel.

* Investigating the disappearance of critical equipment.

* Trying to analyse the events leading to an accident.

The technology provides mine management with real-world solutions by adding the proverbial 'last mile' link to many daily operational problems. To paraphrase Albert Einstein, “One cannot use yesterday’s solutions to solve today’s problems, or tomorrow’s.”

Safety and productivity

The requirements and high demands imposed on mine management by the stakeholders include safety and productivity.

Safety, a white hot topic and the flavour of the day, relates directly to injury and fatalities of people, and damage to property. South Africa’s poor track record in this regard has forced government to re-address the issue and we could soon see new laws tabled, which will negatively influence any player who does not comply.

Productivity directly influences production, which influences profits. It is related to the effective management and utilisation of all the assets (people, plant and equipment).

Do you know what your exact production figures (ore through the tips) were for the past eight hours? Do you know the status of all your employees? Do you know where all your equipment is? Do you know why a locomotive or vehicle is stationary in a haulage for two hours?

Technologies exist to provide answers to these questions and active RFID is being increasingly applied in these areas.

Continued on the web

For the complete article visit www.instrumentation.co.za/+C9205

For more information contact Clive Wilmans, Core System Integration, +27 (0)11 792 3083, [email protected], www.csisa.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved