The future of IT in mining and manufacturing operations.

Keywords: [automation, convergence, ERP, implementation, integration, forward thinking, global, governance, human, IT, manufacturing business system, manufacturing enterprise system, manufacturing execution system, MES, productivity, S88, S95, scada, SOA, standards, strategic]

Abstract

In this paper Gavin Halse focuses on the challenges faced on the plant floor and the role of IT systems in the operations environment. Several examples and case studies of innovative operational systems in areas such as safety are presented. The key success factors of system implementation are highlighted together with the learning points from these projects.

Introduction

Business leaders in mining and manufacturing have to balance many conflicting priorities – for example raw material procurement, fixed cost reduction and improved service levels while securing and retaining the necessary skills to remain competitive. The CEO is also accountable to numerous stakeholders in the areas of governance, fulfilling board and fiduciary duties, coping with increasing legislation and mitigating new business risks relating to global market volatility.

In this environment it is imperative that production plants operate predictably. Business leaders cannot focus on every detail of day to day operations and are therefore forced to delegate many responsibilities to operations personnel. However, notwithstanding this delegation, management remains unambiguously accountable for total business performance. In this environment IT-based systems can play a vital role as tools to automate operational processes.

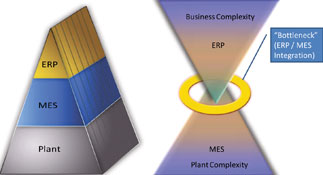

From a business perspective, ERP has now matured. Vendors have recognised that despite the strategic role of ERP in manufacturing, much of the actual working environment on plants is still reliant on information unrelated to ERP, such as safety, engineering, technology and process modelling. This reality demands a renewed vision for the future role of IT in manufacturing.

In plant environments the focus has until now been mainly on plant automation and manufacturing execution systems (MES). As systems matured, plant historians and other scada data analysis tools have become widely used by engineers and production staff to optimise plant operations. The software standards such as S88 and S95 to define and connect plant data with business data are based largely on the presumption that fully automated operations can be achieved through integration of plant with business systems. The concept of the 'realtime enterprise' was at one stage seen as the goal. In practice, the wisdom of tightly coupled and integrated systems has to be challenged and it is asserted that the realtime enterprise is a myth: that information is in fact relevant in several time dimensions, from realtime process control to business lifecycle management over many years.

Time for new strategic thinking

It is almost eight years after Y2k and we find the technology industry once again at a point where several major trends in IT and manufacturing systems are about to have a impact on the business use of IT systems into the future.

Business leaders are now, more than ever before faced with really difficult choices relating to technology strategy. These choices extend far beyond the unimaginative selection of a single vendor solution. Business leaders need to be able to relate their IT strategy to anticipated business drivers over the next 5-10 years. The decisions they take now will have a significant impact on the agility, efficiency and ultimately profitability of their individual mining and manufacturing companies going forward.

Continued on the web

For the complete article visit www.instrumentation.co.za/+C9211

For more information contact Gavin Halse, ApplyIT, +27 (0)31 275 8080, [email protected], www.applyit.com

© Technews Publishing (Pty) Ltd | All Rights Reserved