Mori Tower uses Citect facilities to improve tenant service, reduce operating costs and optimise energy utilisation.

The Mori Building Company was founded in 1959 and has over 1000 employees. The company is involved in all aspects of the urban landscape, from redevelopment to the design supervision, operation and management of residential and commercial facilities. Its new headquarters at Mori Tower in central Tokyo, occupies 11,6 hectares, and is one of the largest redevelopment projects undertaken in Japan. One of the key objectives was to implement a flexible system for centralised monitoring and control of multiple facilities.

Solution evaluation

Citect, its Japanese Partner Fuji Electric Systems, and Mori’s systems integrator (SI), delivered a fully automated state-of-the-art facilities monitoring solution that provides instantaneous information on the entire Mori Tower. CitectFacilities was selected for its open, reliable and scalable system with hot-backup and full redundancy. It was able to easily integrate climate, lighting and other controllable devices from multiple facilities, providing building-wide processing of data from a multitude of points, monitored in realtime.

Open standards

As the Mori Tower has significant numbers of areas to be controlled, it was decided to choose an open method of communications based on the OPC standard. Citect is an OPC Foundation member and CitectFacilities is both an OPC Server and OPC Client, a true reflection of open data exchange.

System capability

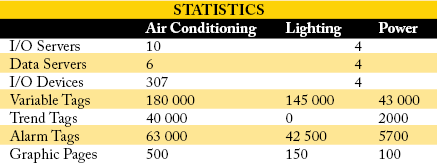

More than 368 000 points are monitored in the building, with 64 projects included in one common runtime database. More than 42 000 trends and 110 000 alarms are configured in the system. Read-on demand technology was chosen to eliminate unnecessary server access, only points requested by the client are displayed. This technology allows the system to handle the vast amount of data allowing users to view continuous alarm states, trends at pre-defined rates and current active display pages for the data they want, when they want it.

Structured engineering

CitectFacilities’ ability to include multiple individual projects into a single runtime database, allows several systems integrators to work simultaneously. By defining a structured tag naming convention, people from various companies specialising in airconditioning, lighting and power engineering can all work on a common variables database.

The benefits

Using CitectFacilities, Mori Building was able to successfully integrate power, lighting, HVAC systems and other controllable devices from multiple facilities. This enabled Mori Building to achieve its business objective of implementing a 24-hour continuous enterprise-wide monitoring and control system, with full redundancy of server tasks.

“The big advantages users get from CitectFacilities are the ease-of-use and maintenance upgradeability. Citect ensures that customers have a system platform capable of growing with them as the system requirements become more sophisticated,” says Mr Toshihiko Tatsuki, general manager, Fuji Electric Systems.

For more information contact Niconette du Toit, Citect Africa, +27 (0)11 699 6600, [email protected], www.citect.com

© Technews Publishing (Pty) Ltd | All Rights Reserved