Land Ladle Safety System: automated torpedo car refractory monitoring

November 2007

Temperature Measurement

The problem

Integrated steel mills use torpedo cars to transport molten metal from the blast furnace to the steelworks. Each car has a torpedo shaped ladle that can carry up to 250 tons of liquid metal. The ladle is lined with refractory brick to keep the contents liquid and protect the outer steel shell. The volatility and erosive nature of molten metal make monitoring the torpedo car's refractory lining a vital maintenance function. The consequence of a breakout is considerable, in terms of safety and cost. A single breakout can cost US$250 000 or more.

Solution

The Land Ladle Safety System, which uses a Landscan Infrared Linescanner, produces highly detailed thermal profiles of each side of the car from a short distance. This enables the Safety System to view very small surface details.

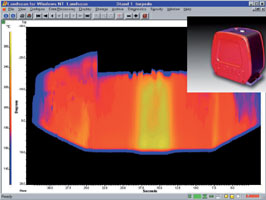

Thermal profile of a torpedo car showing measurement zones

As each car passes a measurement station, ID tags on the car provide a car number and temperature data to the monitoring software. The direction of movement is also detected.

An image file is automatically saved for each side of every car with the same information. In addition, the complete view is divided in areas (50 for example). For each area the maximum and average temperatures are stored in an historical database. This provides long term trending of individual areas on each torpedo car. This database and stored images are accessible from computers on the company network. It is also possible to transfer data to the company process control system for further analysis and storage.

System benefits:

* Avoidance of a breakout and its consequences - time, material, labour.

* Automated process - saves cost and man time.

* Historical thermal image database of both sides of every car.

* Analysis of area data over a long time can reduce refractory relining cost, by permitting more runs between relines and the ability to do partial relines.

* Increased safety.

* Improved confidence in refractory condition and safety of cars.

* Planned refractory relining maintenance schedule.

Landscan temperature measurement system

The Landscan LSP series linescanner head is extremely compact and has a minimised depth and base footprint. A built-in laser targeting system aids alignment on to the target.

Features

* Compact size with robust sapphire window.

* Wide angle 80° scan.

* Scan speed 10-100Hz (adjustable).

* 100:1 field of view (95% energy).

* Built-in laser to define scan plane and angle.

* Single cable connection.

The output from the linescanner head is converted into a data string of 100 readings per scan line with a maximum frequency of 100 lines/second and is transmitted to a Landscan Control processor. The Landscan Control processor provides all the calculations required, such as zone output and alarms for each scan line. The Landscan Control Batch (LSC-B) provides additional product orientated functionality. LSC-B can detect, in conjunction with the ID tag reader, the beginning and end of the torpedo car and stores the measured data internally. The LSC-B calculates area temperatures, based on this two dimensional array. For a torpedo car the array is typically divided into 50 fields (5x10).

For more information contact Jerry Smits, Protea Automation Solutions, +27 (0)11 719 5792, [email protected], www.protea.co.za

Further reading:

Decarbonising a heat and power plant

Valmet South Africa

Temperature Measurement

Valmet is delivering a boiler fuel conversion for a combined heat and power plant in Poland. After modernisation, coal will be replaced entirely with certified forest biomass supplied by local providers.

Read more...

High-precision fill quantity control in food supplement production

Temperature Measurement

Vital Products was looking for a precise and efficient solution to check the weight and ensure the completeness of its products. Minebea Intec, a specialist in industrial weighing and inspection technologies, was able to provide a solution.

Read more...

Infrared solutions for glass manufacturing challenges

Temperature Measurement

In the glass industry, infrared temperature monitoring is crucial for maintaining product quality and process efficiency. Instrotech has infrared sensors and cameras which provide non-contact temperature measurements, making them ideal for these high-temperature environments.

Read more...

Intelligent process stabilisation in injection moulding

Temperature Measurement

A new benchmark in precision temperature control for plastics processing is being set by technotrans.

Read more...

New temperature transmitters with Profibus connectivity

Temperature Measurement

Siemens is enhancing its temperature measuring device portfolio with the transmitter duo, Sitrans TH420 PA and Sitrans TF420 PA. Both devices feature Profibus connectivity, advanced safety functions and expedited commissioning all in one unit.

Read more...

Enhancing industrial efficiency through advanced temperature control

Iritron

Temperature Measurement

Iritron has been offering modular smart thyristor drives to the local and international mining, minerals and metals market, including the latest new leading innovations in temperature control technology. These drives combined with advanced proportional-integral-derivative (PID) control will change the way large industries manage their heating processes, reducing costs and extending equipment lifespan.

Read more...

Non-contact infrared thermometer

Temperature Measurement

AMETEK LAND has developed a new non-contact infrared thermometer for precise measurement and control during deposition processes in optical fibre manufacturing.

Read more...

The critical role of temperature measurement in flame hardening

Instrotech

Temperature Measurement

Flame hardening is a heat treatment process widely used on parts made from mild steels, alloy steels, medium carbon steels and cast iron. Accurate temperature measurement is not just important, but critical for the success of flame hardening.

Read more...

Noncontact infrared temperature control in aluminium rolling process

Instrotech

Temperature Measurement

The aluminium rolling process is critical to the aluminium manufacturing industry, where precise temperature measurement is essential for ensuring high-quality product output and protecting equipment. The Optris long-wavelength camera can accurately measure strip temperatures in cold rolling and coiling applications.

Read more...

Where simplicity meets reliability

Endress+Hauser South Africa

Temperature Measurement

The new iTEMP TMT31 temperature transmitter from Endress+Hauser combines simplified selection, ordering, installation and operation with the highest reliability and long-term stability in one product.

Read more...