Beijing local wastewater treatment

October 2007

PLCs, DCSs & Controllers

Chen-Hua, application engineer, Advantech, Beijing

With the help of Adam-5510 PC-based programmable controllers, Beijing's wastewater treatment plant has successfully built a reliable wastewater process control system. This has provided it with a saving over using a traditional PLC solution.

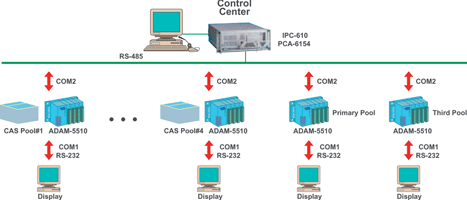

System architecture of Beijing water treatment plant

In the past, because of plentiful labour and relaxed environmental restrictions, the quality of wastewater treatment and the output of clear water at Beijing's treatment plant were not closely monitored. Recently, local government has required the plant manager to solve these quality problems and reduce staffing levels.

Process

The process of wastewater treatment involved at the plant has three principal steps:

* Filter out the particulates in the wastewater pumping room and de-sanding pool.

* Add chemical to the water in the four CAS (carbon absorption system) pools.

* Drain the intermediate water into the purification pool for the final refining process.

Key requirements

The key requirements for the replacement system were that it should:

* Integrate widespread data from the different pools and respond to the control centre reliably and quickly.

* Collect and process the data in a timely and accurate manner.

* Operate with reduced staff levels.

System description

Advantech Beijing developed a PC-based process control system using Adam-5510 controllers to solve the plant's need. There are six PC-based Adam-5510 programmable controllers installed at the CAS pools, de-sanding pools and purification pools. These monitor and control the field devices. The plant equipment status is shown on a field display and simultaneously fed back to the control centre through an RS-485 network. The system also uses Adam-5060 6-channel relay output modules, Adam-5051 16-channel DI modules for facilities monitoring and Adam-5017 8-channel AI modules for flow rate and volume monitoring.

At the de-sanding pool the Adam-5510 handles pump on/off control, gate open/close control, and monitoring of input flow rate, water level and related equipment's on/off and alarm outputs.

In the CAS pools the Adam-5510 responds to commands from field stations or the control centre to control the four sub-steps in each CAS reaction. One important function is to detect fully automatic or semi-automatic signals and respond promptly with control logic.

At the purification pool, 10 purification devices are monitored and controlled by the programmable controllers. The control processes are similar to those used in the CAS pools and also feature automatic and semi-automatic modes.

The benefits that the Adam controllers provide in this data acquisition and control system are:

* Flexibility of communications.

* Data memory storage capacity.

* Ease of programming with the C language.

* A distributed data acquisition system architecture.

For more information contact Peet Smit, Centurion Micro Electronics, +27 (0)12 666 9066, [email protected], www.cme.co.za

Further reading:

All eyes on the modern DCS platform

Schneider Electric South Africa

PLCs, DCSs & Controllers

Modernised DCS platforms are no longer confined to hardware-dependent architectures. These systems have evolved to combine the strengths of both PLCs and DCS while adding capabilities that make them more open, resilient and collaborative.

Read more...

Automation solution for waste management at incineration facility

PLCs, DCSs & Controllers

Valmet is to deliver an automation system to Seongnam City’s incineration facility currently under construction in South Korea. By leveraging intelligent automation, the plant will optimise energy production, minimise emissions and deliver efficient, consistent performance throughout its entire lifecycle.

Read more...

Valmet’s supplies DCS to Europe’s largest electric boiler plant

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system to Helen’s Hanasaari electric boiler plant and a thermal accumulator being built in Helsinki, Finland. Once completed, it will be Europe’s largest electric boiler plant.

Read more...

Technology blueprint paves way for e-methanol fuel expansion

Schneider Electric South Africa

PLCs, DCSs & Controllers

Schneider Electric has delivered the technology stack behind European Energy’s Kassø Power-to-Xfacility, the world’s first commercially viable e-methanol plant.

Read more...

PCS Global delivers turnkey MCC installation in Botswana

PCS Global

Editor's Choice PLCs, DCSs & Controllers

PCS Global is delivering a turnkey containerised MCC installation for a major copper mining operation in Northwest Botswana.

Read more...

New energy-efficient evaporation line for dissolving pulp production

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s €75 million project to convert the Biotek mill to produce dissolving pulp for the textile industry.

Read more...

Valmet modernises turbine automation

Valmet South Africa

PLCs, DCSs & Controllers

Valmet has received an order to deliver a comprehensive replacement of plant DCS and turbine control systems at Ennatuurlijk’s combined cycle power plant in the Netherlands.

Read more...

Hybrid DCS for an evolving industrial landscape

Schneider Electric South Africa

PLCs, DCSs & Controllers

Today’s industrial automation continues to evolve at a blistering speed, which means traditional DCSs have to keep up to ensure continuous integration into modern, digital infrastructure.

Read more...

IIoT controller for the field and control cabinet

ifm - South Africa

PLCs, DCSs & Controllers

The IIoT controller from ifm is a powerful, communicative and flexible PLC solution in machine and plant digitalisation.

Read more...

Bringing the benefits of Ethernet to hazardous industrial environments

ABB South Africa

PLCs, DCSs & Controllers

Christian Johansson, global product manager for ABB Process Automation explains how Ethernet-APL lets plant owners unlock more value from their process data, optimise performance and promote safer operations.

Read more...