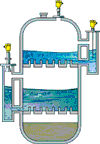

Distillation columns are used in the refining process for the production of petroleum products. After crude oil has been desalinated and cleaned, it is fractionated into its constituent parts in distillation columns. At temperatures up to 400°C, the mainly gaseous crude oil is transported to the distillation column and then condensed in intermediate stages at varying temperatures. The lower the boiling point of the product, the higher the condensate ascends up the column. For optimum column operation accurate temperature, pressure and level measurement are of paramount importance.

Radar level measurement

In the past, displacer systems in bypass tubes were used for level measurement in distillation columns. Today, these maintenance-intensive systems, which suffer from residue build up, are being replaced with non-contact radar sensors. Existing bypass tubes can usually be used for the installation, so no significant mechanical modifications are necessary. The high product temperatures in the lower part of the column require special sensor types. The Vegapuls 66 radar sensor, which has ceramic materials in the antenna system, is suited to these process conditions because of its operating temperature of up to 400°C and its pressure capability of up to 160 bar.

Guided microwave level measurement

The implementation of guided microwave sensors in the reference vessels (bypass tubes) of distillation columns is a viable alternative to non-contact radar sensors. When installed in the tube of the reference column, the rod of Vega’s guided microwave sensor and the bypass tube form a coaxial system. The microwaves travel as in a coax cable and lateral equalisation holes cause no signal interference. Even products with a dielectric constant less than 1,7 can be reliably measured in this configuration. The Vegaflex 66 is not influenced by temperature, density and pressure changes in the measured medium and is unaffected by build up on the vessel wall or on the sensor rod. This microwave solution can be used for operating temperatures up to 250°C.

Pressure measurement

An important value to monitor in the distillation process is the top pressure at the upper end of the column. Depending on the process, distillation columns operate under vacuum or at extremely high pressure. Vega’s Vegabar 61 pressure transmitter, with its wide temperature range, is well-suited for this application. The device is capable of withstanding the extreme temperature fluctuations experienced during the start-up phase in the column. The sensor version with isolator can be implemented for temperatures up to 400°C.

For more information contact John Groom, Vega Instruments SA, +27 (0)11 958 1901, [email protected], www.vega.com

| Tel: | +27 11 795 3249 |

| Email: | [email protected] |

| www: | www.vega.com/en/home_za |

| Articles: | More information and articles about VEGA Controls SA |

© Technews Publishing (Pty) Ltd | All Rights Reserved