In 2007, 11 years after releasing the first version, Siemens AG has launched version 7 of its Simatic PCS7 process control system. It offers plant operators added value in the form of integrated alarm management, asset management, industrial network security, increased plant availability, validation support and open systems connectivity.

Integrated alarm management

The most frequent reasons for plant shutdowns are incorrect operator actions due to plant alarms not being as effectively processed as they could be. According to studies by NAMUR, the number of alarms that can be processed by operator teams in process-engineering plants is about 150 per day. The actual number of alarms that occur, however, is several times larger. Very few of these alarms are relevant to safe operation of the plant. The problem is that these safety-relevant alarms are lost in the flood of less-important messages.

The integrated alarm management system in version 7.0 records all alarms and messages but blanks out irrelevant ones at the operator stations. With the help of this function, up to one third of the less important alarms are blanked out dynamically. Alarm prioritisation, alarm categorisation and additional action instructions actively support operators in their alarm handling.

Asset management

The new version of PCS 7 offers the user the advantages of central engineering, detailed diagnostic features and integration of these devices in the plant-related asset management system. Non-intelligent plant components may also be integrated in this system. An AS proxy module has been developed to monitor mechanical assets such as heat exchangers, tanks, pumps and motors. With the help of this programmable function block, disallowed operating states can be deduced. This proxy module can also be used to feed maintenance alarms into the asset management system.

Industrial network security

A completely different form of safety is offered by the comprehensive industrial security concept of version 7.0. The increase in the networking of individual plant levels and the widespread use of standard IT systems based on Microsoft Windows is escalating the danger of hacker attacks on automation and process control systems. Therefore, a comprehensive security concept has been created to ensure overall plant safety. The entire plant is divided into individual safety cells with defined and monitored access points. The aggregation of safe self-enclosed cells results in a protected overall system.

Increased plant availability

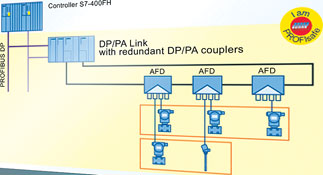

Increased plant availability is one of the central value-adding issues for plant operators today. At Siemens, the focus for the new version has been on Profibus PA. Whereas Profibus DP was developed for communication with distributed field devices and is equipped with a redundancy concept, Profibus PA, which enables not only communication but also power supply via a two-wire line, was not previously designed in a redundant form. A newly developed concept, consisting of couplers and intelligent field distributors as the hardware elements, now fills this gap. In the event of coupler failures, short-circuits and cable breaks as well as in the absence of bus termination, full process control is guaranteed with the redundant Profibus PA. The couplers can be integrated in the plant-related asset management system by means of EDD (electronic device description).

Validation support

Plants (such as pharmaceutical manufacturing facilities) in regulated industries, which are subject to a validation obligation, are making greater demands in respect of traceability and archiving. The requirements of the US FDA (Food and Drug Administration) require access control, version management and traceability by means of change reports. The recording options of the PCS 7 change logbook range from all online changes in automation systems, operator systems, batch administration or route control to the recording of library and element changes.

Open systems

Higher-level systems for process data evaluation and production planning systems are important levers for process optimisation and the reduction of operating costs. The Open PCS 7 interface, based on the OPC specifications, has been implemented for greater process-data availability. An optional Open PCS7 client/server package facilitates access to process data, which are now accumulated at a central point.

For more information contact Keshin Govender, Siemens Southern Africa, +27 (0)11 652 2412, [email protected], www.siemens.co.za

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved