Realtime location system improves safety, security and workflow

July 2007

PLCs, DCSs & Controllers

A realtime location system (RTLS) locates and tracks physical objects, such as mobile equipment and employees, in realtime. The position of an asset becomes a new type of process control variable, used to reinforce safety practices, improve security, and simplify operational and maintenance workflow optimisation.

Honeywell's RTLS integrates with the company's Experion Process Knowledge System (PKS) and the Enterprise Building Integrator (EBI) to deliver realtime location information from across the plant. The solution uses three positioning technologies: global positioning system (GPS), ultra wideband (UWB) and a proprietary active radio frequency identification (RFID). Its HTML-based interface allows users to locate and track assets on 2D or 3D maps and view query results.

Safety practices reinforced

Localisation sensors installed in key locations across the plant allow emergency teams to generate mustering reports within a few seconds of an incident and locate any missing or injured employees. The system provides automatic notification with the exact location of an injured employee, sending signals only when within the vicinity of a sensor (up to approximately 200 m).

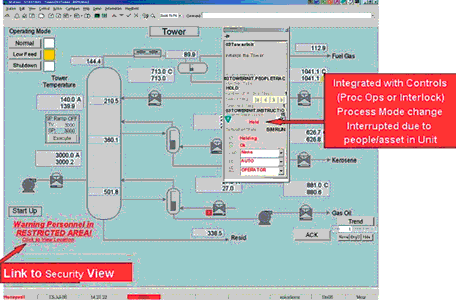

Asset location is another variable to manipulate during plant operations. Some procedures or situations require specially trained staff to be present in a specific perimeter. For example, users can build interlocks that take into the account the location of workers in the field and ensure that procedures are started only when an authorised staff member is in the perimeter. The combination of Honeywell's RTLS and Procedural Operations tools allow users to take safety to the next level.

Procedure interlocked as non-authorised personnel in restricted area

Improved security

Honeywell's RTLS complements the user's investment in access control and perimeter security by providing a means to manage its facility's employee and visitor traffic within the plant. The system is compatible with Honeywell access cards and digital video cameras that may already be installed at a facility

Operational and maintenance workflow optimisation

The system allows users to quickly locate and track inventory and valuable assets moving inside and outside the plant. Time spent looking for assets can be dramatically reduced, which can have significant benefits during major turnarounds and new construction projects.

For more information visit www.honeywell.com/ps or contact Jason Whitehead, Honeywell Southern Africa, +27 (0)11 695 8000, [email protected], www.honeywell.co.za

Further reading:

All eyes on the modern DCS platform

Schneider Electric South Africa

PLCs, DCSs & Controllers

Modernised DCS platforms are no longer confined to hardware-dependent architectures. These systems have evolved to combine the strengths of both PLCs and DCS while adding capabilities that make them more open, resilient and collaborative.

Read more...

Automation solution for waste management at incineration facility

PLCs, DCSs & Controllers

Valmet is to deliver an automation system to Seongnam City’s incineration facility currently under construction in South Korea. By leveraging intelligent automation, the plant will optimise energy production, minimise emissions and deliver efficient, consistent performance throughout its entire lifecycle.

Read more...

Valmet’s supplies DCS to Europe’s largest electric boiler plant

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will supply an automation system to Helen’s Hanasaari electric boiler plant and a thermal accumulator being built in Helsinki, Finland. Once completed, it will be Europe’s largest electric boiler plant.

Read more...

Technology blueprint paves way for e-methanol fuel expansion

Schneider Electric South Africa

PLCs, DCSs & Controllers

Schneider Electric has delivered the technology stack behind European Energy’s Kassø Power-to-Xfacility, the world’s first commercially viable e-methanol plant.

Read more...

PCS Global delivers turnkey MCC installation in Botswana

PCS Global

Editor's Choice PLCs, DCSs & Controllers

PCS Global is delivering a turnkey containerised MCC installation for a major copper mining operation in Northwest Botswana.

Read more...

New energy-efficient evaporation line for dissolving pulp production

Valmet South Africa

PLCs, DCSs & Controllers

Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s €75 million project to convert the Biotek mill to produce dissolving pulp for the textile industry.

Read more...

Valmet modernises turbine automation

Valmet South Africa

PLCs, DCSs & Controllers

Valmet has received an order to deliver a comprehensive replacement of plant DCS and turbine control systems at Ennatuurlijk’s combined cycle power plant in the Netherlands.

Read more...

Hybrid DCS for an evolving industrial landscape

Schneider Electric South Africa

PLCs, DCSs & Controllers

Today’s industrial automation continues to evolve at a blistering speed, which means traditional DCSs have to keep up to ensure continuous integration into modern, digital infrastructure.

Read more...

IIoT controller for the field and control cabinet

ifm - South Africa

PLCs, DCSs & Controllers

The IIoT controller from ifm is a powerful, communicative and flexible PLC solution in machine and plant digitalisation.

Read more...

Bringing the benefits of Ethernet to hazardous industrial environments

ABB South Africa

PLCs, DCSs & Controllers

Christian Johansson, global product manager for ABB Process Automation explains how Ethernet-APL lets plant owners unlock more value from their process data, optimise performance and promote safer operations.

Read more...