Global research shows an astounding 85% failure rate in achieving the desired benefits for companies that have installed supporting technology solutions without proper consideration of their business objectives, process definitions and standard practices. In contrast, companies that clearly identified their business objectives, defined process definitions and underwent a best-practice selection initiative achieved an average of 30% efficiency improvement without installing any supporting technologies.

"These facts show why it is important not to simply purchase products from a vendor and to think that just installing them would improve a plant or overall business," argues Rockwell Automation South Africa & Middle East MES consultant, Jacques van Eeden. "A company looking to automate or improve its business should partner with a solution provider that can guide management through the business process that should precede such an important investment."

Industrial firms polled recently revealed spending an average of 40% of their IT budgets on the creation of self-made solutions like spreadsheets and other means to try and keep track of important data. In addition to this endless spending requirement, these companies are wasting 30% of employees' time searching for relevant information, as 85% of the information gathered in this manner is unstructured and up to 42% is paper-based. Sixty percent of the CEOs surveyed expressed a need 'to do a better job capturing and understanding information rapidly in order to make swift business decisions'.

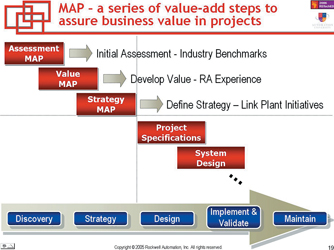

Rockwell Automation believes its high success rate in delivering supporting technology that achieves the total integration of a business's information, automation and control requirements is due to the global organisation's consultative approach. "Instead of just winning a contract, installing our products and departing, we approach these projects in a structured manner," Van Eeden explains. "There is a crucial information gathering, processing and interpretation function for us to fulfil. Our first task is to capture the current state of the client's organisation through a series of interviews with all stakeholders. We then facilitate the required interaction between all relevant parties within the organisation, if necessary, to derive clear business objectives, well defined business processes and a complete assessment of best practices."

At this point in the roadmap or planning system followed by the factory information specialist, its industry experts take industry benchmarks and its experience in similar projects around the world into consideration when advising a client with regard to the supporting technologies required to achieve the goals that were defined in the first phase of the consultative process. Budget and other constraints are balanced with alternative suggestions to optimise the individual plant or process in question to ensure that the solution that is finally implemented not only suits the unique needs of the client, but also allows for total integration of data throughout the organisation.

"This is where our value proposition comes in," Van Eeden enthuses. "We are able to do so much more than provide world-class technologies. We can provide the objective perspective that is often required in these situations. Our engineers are often able to streamline the client's business processes and find better ways of using the available resources. By doing this, we regularly save customers money in ways that are not directly linked to the benefits and features offered by our products and technologies."

Once a strategy map has been set up to link plant initiatives with the constraints faced, user requirement specifications are carried out and a total, integrated solution is proposed and implemented. Van Eeden points out that the training and maintenance support that follows the supporting technology installation is crucial in ensuring total buy-in from the operational staff, and the overall success of the project.

"Companies should not look at Rockwell Automation and see a provider of PLCs, scada packages and MES systems, they should look to us for the business solutions that we offer," he continues. "Buyers do not have to be left dazed by the host of products, features and systems available in the market, when there are solution partners that could facilitate the proper implementation of whatever improvements their operations require."

For more information contact Jacques van Eeden, Rockwell Automation South Africa & Middle East, +27 (0)11 654 9887, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved