Temperature is a commonly measured industrial process parameter. Most temperature measurements are made using the contact devices like thermocouples or RTDs, but for many applications involving moving or batch-heated products, these contact devices can only be used to provide a direct measurement of the product's surface temperature. In many heating operations, direct temperature measurement is a critical control parameter for the optimisation of product quality and process productivity.

Infrared thermometers use an optical system to collect infrared energy from a measured target area. This energy is used to calculate the target surface temperature. The measured temperature can be displayed on a digital meter, or it can be in a form of an analog output signal that varies linearly with temperature. These temperature output signals can be input into a computer, controller or other device for process monitoring and control.

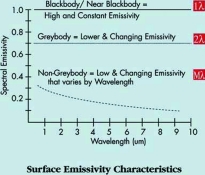

There are three different types of infrared thermometers which offer unique capabilities for specific application requirements. These include sensors with single wavelength (ratio) and multiwavelength designs. While there are many factors that affect the selection of a sensor, one of the most important considerations is the emissivity characteristics of the measured surface. Emissivity is a technical term used to quantify the amount of energy emitted from a surface relative to its theoretical maximum for a given temperature. In general, most applications can use a single wavelength sensor because most materials exhibit a high and constant emissivity. However, for accurate and reliable measurements on most metal materials, where the emissivity is low or can vary, then the dual and the multiwavelength sensors are recommended.

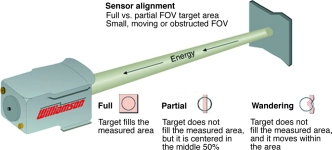

Williamson temperature sensors use a fixed optical system to 'focus' on the desired target area. Consequently, the selection of the sensor's optical resolution or field of view (FOV) is important because it defines the measured target area that is used by the sensor to determine the object's temperature.

Sensors offer a variety of sighting capabilities that include a line of sight, visual aiming and fibre-optic sighting. The sensor's temperature range is the optimal range for the sensor's detector, filter and optics. It can be specified in either a Fahrenheit or Celsius scale. Using the sensor's text-based menu system, it is possible to configure the temperature range to a narrower span and to convert all of the sensor's temperature-based parameters between the Fahrenheit and Celsius scales.

The sensor's spectral response defines the wavelength of the energy measured by the sensor. Each sensor's filters are defined in a narrow band that operates in an atmospheric window that eliminates distance sensitivity. The sensor provides both analog and digital outputs, in both a standalone and system configuration with an optional interface module.

The Williamson PRO Series text-based menu system offers access to a wide range signal conditioning and diagnostic capabilities. Specifically, they include adjustable settings for emissivity compensation, averaging time, peak hold functions, as well as options for on/off control and alarm capabilities.

For more information contact Andy Brown, Temperature Controls, +27 (0) 11 791 6000, [email protected]

| Tel: | +27 11 791 6000 |

| Email: | [email protected] |

| www: | www.tempcon.co.za |

| Articles: | More information and articles about Temperature Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved