Condition monitoring: modern answers - age-old methods, Part 2

July 2006

Maintenance, Test & Measurement, Calibration

In the June 2006 issue of SAI&C, we looked at a bit of the history of SPM Instrument, specifically in South Africa. We did not discuss why it was so popular in its heyday or even what the method does. We trusted that the bit of nostalgia was enough to trigger your memory.

Now we will get down and dirty (or wet). SPM orginated from the shipping industry. A Danish shipowner was getting very upset about untimely bearing failures on his ships. He then commissioned a certain Eivind Sohoel to develop a method of predicting these failures. But how to do it? This was the sixties remember - no Internet or computer to help search for methods. The screwdriver was the answer! When people listen to a bearing they can get a fairly good idea of how well the bearing is doing. However, everybody hears and interprets the sound differently.

First take out the ear by replacing it with a microphone. But we still have a problem! Environment noise can distort the noise picture. Is it not too late when a bearing is making an audible noise? Should one not try and pick it up sooner?

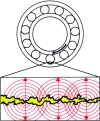

Using a microphone that measures in the ultrasonic range resolves this issue. During the research Sohoel found that sharp repetitive shocks (ultrasonic sound waves) are generated by bearings.

It was also established that the shocks are generated by impact. But what influences the amplitude of these shocks?

Tests also showed that the impact amplitude is a function of the impact speed as well as the shape of the impacting edges. If one takes the shape and depth as an indication of damage (one certainly does not want craters in the rolling element or bearing races) then the only variable left is the speed. If one knows the rotational speed of the bearing and its diameter one can calculate the circumference speed. By then testing a lot of 'good' bearings one can empirically determine the relationship between speed, the bearing diameter and the impact shock amplitude.

Thus having done this one is able to use the absolute shock level measured on the bearing and by subtracting the speed and diameter influence one has a residual value which can be linked to bearing damage. By then testing various bearings in different damaged states one is able to empirically determine the shock levels that spells disaster. It is that simple! Next issue we will look at what else the shock pulse method can reveal.

For more information contact Vegter Condition Monitoring, 011 849 6876, [email protected]

Further reading:

OEM-standard repairs for industrial gear units

Maintenance, Test & Measurement, Calibration

BMG, the official OEM for Hansen gearboxes, is authorised to repair Hansen industrial gear units in strict accordance with the manufacturer’s documented procedures, preserving the design tolerances and operational reliability required in demanding industrial environments.

Read more...

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...

Automated test and measurement

Comtest

Maintenance, Test & Measurement, Calibration

Comtest, in partnership with global brands, provides customised solutions with integrated hardware and software for efficient testing and data collection.

Read more...

Advanced field calibrator and communicator

Maintenance, Test & Measurement, Calibration

The Beamex MC6 is a high-accuracy field calibrator that offers automatic calibration capabilities for pressure, temperature and various electrical signals.

Read more...

Inline particle measurement

Mecosa

Maintenance, Test & Measurement, Calibration

Part of the SOPAT family, Parsum has for more than 20 years stood for the measurement of particles in a running process - without sampling and without a laboratory.

Read more...