High temperature, pressure and noise are all conditions found in abundance in the steel and metal industries. The benefits of using non-contact microwave radar for process level measurement in these conditions are numerous.

Within the total of over 100 000 non-contact radar devices supplied by VEGA worldwide into these industries, solutions already provided include: installation in blast furnaces 'burden level' and surface profiling; mould levels; viewing through refractory into aluminium smelters; as well as level measurement of raw supply materials such as coal (raw and pulverised), coke, ore and lime. The radar sensors have also been used for liquids such as oil, acid, alkali and for boiler levels and effluent. Even distance monitoring applications for over conveyors, gas-holder roof levels, overhead cranes and hot coil positioning have been successful.

A non-contact microwave radar's main advantage in the steel industry is that it is virtually unaffected by the process material or temperature. Its non-contact capabilities make it a suitable solution when the temperatures are extreme, with molten metals in the range of 1200 to 1600°C. Radar is also unaffected by dust and filling noise and the new 70 m long-range systems have been specially developed for the measurement of solids in silos, which makes them ideal for burden level monitoring too.

Difficult application

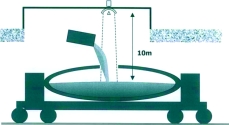

One difficult application where radar has been successfully applied is continuous 'torpedo ladle' level measurement. This is where the iron, tapped from the blast furnace, is poured via a rocking spout into a waiting 'torpedo' shaped, refractory lined vessel, mounted on a railway truck some 5 metres below. The molten iron is then transported to the BOS converter plant to be turned into steel in a separate process. The 'torpedo' rotates on its axis to discharge the molten iron.

Pouring a stream of molten iron into an oval hole approximately 1 metre by 2 metres wide, 7,5 metres away, is a skilled and hazardous operation. Any overfilling or spillage can cause major damage to the rail car and track as well as extreme danger to personnel in the area, not forgetting loss of production whilst clean up and repairs are made. If the vessels are not filled to an optimum level, under-utilising their capacity, transport costs increase and furnace output is jeopardised, further adding to the overall costs of production.

A Vegapuls radar is now being used to reliably monitor the level of this filling process. It has been trailed extensively at a Corus, UK site for the last year and has proven its reliability and performance over other (FMCW) radar systems installed in the same application, at a fraction of the cost. The Vegapuls radar is a 2-wire loop powered device, mounted in the extraction hood approximately 7,5 metres above the top of the torpedo rail car. The transmitter uses high frequency microwaves at 26 GHz to provide sharp focusing. The radar is fitted with a parabolic antenna design, further narrowing the beamed signal and making it focused enough to reliably look down, alongside the filling stream of metal and through the vessel hole to monitor the level some 10 metres away.

By using pulsed radar microwaves, the system is able to work under these extreme conditions. VEGA's PACTware software programme also enables engineers to easily 'see what the radar sees' remotely. In addition, Echofox signal processing gates out unwanted signals and interference from the filling stream including the clouds of fume generated.

As a result of this, a total of eight more systems are to be ordered to monitor all the fill points under the blast furnace. "We have monitored the performance of over 500 fills and are very pleased with the reliability, accuracy and performance", said the Corus TCP engineer. The narrow focusing of the Vegapuls radar, combined with software performance, VEGA support and experience with these applications has resulted in success in this difficult application area.

For more information contact Alan Wynn, VEGA Instruments, 011 958 1901, [email protected]

| Tel: | +27 11 795 3249 |

| Email: | [email protected] |

| www: | www.vega.com/en/home_za |

| Articles: | More information and articles about VEGA Controls SA |

© Technews Publishing (Pty) Ltd | All Rights Reserved