Air wipe for extruded shapes and hose

November 2005

Maintenance, Test & Measurement, Calibration

Exair Super Air Wipe provides a uniform 360° airstream that is suitable for blowoff, drying, cleaning and cooling of pipes, cable, extruded shapes, hose and more. The split design offers easy clamping around the surface of the material moving through it, eliminating the need for threading. All models have stainless steel screws and shims. Stainless steel wire braided hose is also included on sizes up to 102 mm for added corrosion and heat resistance. Aluminium models are rated for temperatures up to 204°C and stainless steel models for temperatures up to 427°C.

Prior to the introduction of this product, the only way to blowoff, dry, clean and cool these surfaces was to use a ring of air nozzles. The high air consumption and the noise levels of the nozzles along with inconsistent air velocity often delivered poor results. The Exair Super Air Wipe provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. The velocity can be varied from a blast to a 'breeze'. Air consumption and noise are low.

The air wipe is easy to use and install. There is a ¼ NPT female inlet on each half of the device on sizes up to 178 mm. Larger sizes include two ¼ NPT female inlets on each half in order to maintain proper air volume and performance. Aluminium Super Air Wipe up to 102 mm include a brass tee that supplies one half directly and a stainless steel wire braided coupling hose rated at 204°C to supply the other half. Stainless steel Super Air Wipe up to 102 mm include a stainless steel wire braided coupling hose rated at 427°C. Larger sizes should be piped directly.

Tapped holes on the back are provided for permanent mounting if the air wipe is not held in place with rigid pipe. Coupling brackets that hold each half of the device together are provided which can be installed or removed quickly if required. How it works:

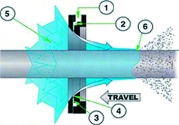

Compressed air flows through an inlet (1) of the Super Air Wipe into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity. This primary air stream adheres to the Coanda profile (4), which directs it down the angled surface of the Super Air Wipe. A low pressure area is created at the centre (5) inducing a high volume flow of surrounding air into the primary airstream. As the airflow leaves the Super Air Wipe, it creates a conical 360 deg ring of air that attaches itself to the surface of the material running through it (6), uniformly wiping the entire surface with high velocity airflow.

Further reading:

OEM-standard repairs for industrial gear units

Maintenance, Test & Measurement, Calibration

BMG, the official OEM for Hansen gearboxes, is authorised to repair Hansen industrial gear units in strict accordance with the manufacturer’s documented procedures, preserving the design tolerances and operational reliability required in demanding industrial environments.

Read more...

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...

Automated test and measurement

Comtest

Maintenance, Test & Measurement, Calibration

Comtest, in partnership with global brands, provides customised solutions with integrated hardware and software for efficient testing and data collection.

Read more...

Advanced field calibrator and communicator

Maintenance, Test & Measurement, Calibration

The Beamex MC6 is a high-accuracy field calibrator that offers automatic calibration capabilities for pressure, temperature and various electrical signals.

Read more...

Inline particle measurement

Mecosa

Maintenance, Test & Measurement, Calibration

Part of the SOPAT family, Parsum has for more than 20 years stood for the measurement of particles in a running process - without sampling and without a laboratory.

Read more...