Motion control in its most basic form means moving an object through the distance between point A to point B at the required speed. To achieve this basic motion most PLC users do not necessarily want to opt for an advanced (and expensive) motion control solution.

Gary Wilson, of Siemens A&D South Africa, says: "I always thought that motion control had to be a complicated affair, but after using the wizards and tools that the S7-200 PLC has to offer my outlook has been changed. After studying the Simatic S7-200 micro PLC (specifically with the EM253 motion control expansion module) - it is remarkable to see just how easy and inexpensive it is to produce basic motion control."

Below is a list of all the hardware and software required to start a small motion control project using the EM253 expansion module:

1. 24 V d.c. power supply.

2. S7-200 CPU222 PLC or larger.

3. EM253 expansion module (one required for each axis).

4. Stepper motor drive (power electronics).

5. Stepper motor (2 to 12 Nm with or without electromagnetic break).

6. S7-200 programming cable (PC/PPI converter cable).

7. S7-200 programming software (STEP7-Micro/Win V3.2 or higher).

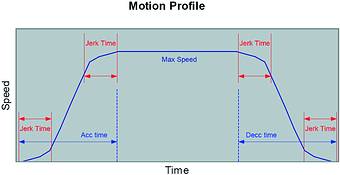

The formula (below) can be used to calculate the required acceleration and deceleration times. A calculation matrix is also available. In this matrix one would just enter the motor maximum angular velocity (ie, 900 rev/min), the motor rated torque and the motor friction torque. The specified jerk times, which round off the curve should always be no more than half the acceleration/deceleration time as if it is too large the motor will also not move as the time to reach maximum speed is further lengthened as seen in the diagram.

Tacceleration = j*Wmax/[Msteppermotor - (Mfriction + Mload)]

Where:

j: Momentum of inertia (mass inertia around axis) = approx 0,005096 kgm2

Wmax: Angular velocity [s-1] (velocity around the axis)

Msteppermotor: Torque of stepper motor [Nm]

Mfriction: Friction momentum at maximum velocity [Nm]

Mload: Load momentum against position direction [Nm]

All the data inserted into the wizard is stored in the S7-200 data area or data block. The wizard does prompt the user for the virtual memory location within the data block. By default the virtual memory location starts at VB0, but this can be changed to meet individual requirements. For instance if the user first employed the wizard to create screens for a TD200 text display, then VB0 to possibly VB100 would be used for the TD200. To make sure that these memory areas do not overlap and cause corruption of data the user should specify that the starting address for the motion profile data. (Possibly VB200 to VB700 depending on the amount of motion profile data.)

There are many other features, which are available in the wizard for the EM253. The user is able to specify the drive's response if either of the limit switches on either end of the motion plane is active and its response to a STOP input. There are terminals on the EM253 module itself where limit switches and stop inputs can be wires. What is helpful is that once the user has specified in the wizard that these inputs will be used in conjunction with the module then no additional programming for this is required in the PLC.

The wizard also allows the user to select if manual motor jogging is required and if the motor starts from a certain reference point on the plane of motion. A switch wired into the EM253 module activates the 'reference point seek' command. Once made the motor will move from left to right along the plane of motion until the reference limit switch is made. There are also various different seeking options available.

Stepper motor drive features

The drive has some helpful troubleshooting LED indicators, which can display if there is a short circuit between motor phases. The OV (overvoltage) and LV (undervoltage) can also indicate to the user if the supply needs to be checked. A rise in temperature indicated with the TMP LED. If the GTE (GATE_N) LED is not active, the user can check to see if the EM253 motion control module is actually signalling to the drive to start the movement. Another really helpful indicator is the RDY (READY) LED, which can be used to visually inform the operator that the reason for no motor movement is a drive fault and not a fault directly on the EM253 or S7-200 PLC. One option that Gary Wilson has used on many occasions is the coupling of the READY2 output from the drive back into the S7-200 PLC. By doing this it is possible to use this input in series with a start command to activate a certain block call or enable signal. There are also other types of outputs, which can also be coupled from the drive back into the PLC, which can be used as indicators.

Unfortunately, position control as far as axis interpolation is concerned cannot be achieved using the S7-200 PLC. However, in the SIMATIC or SINUMERIK range of products there are various other options available. For instance, one level above the S7-200 is the S7-300 PLC, which offers such products like the CPU315T, CPU317T and the FM357 that can be used for synchronous motion control. The SINUMERIK product range enables position accuracy in the (m range. For more advanced tasks where time is a critical factor the S7-400 FM458 can be used and SIMOTION product range is also another option to look at.

Currently, S7-200 motion control solutions are successfully installed by Civet Engineering at AB Tech Packaging and Garden Court Shopping Centre in Cape Town, Powerflo at Daimler Chrysler in East London, National Packaging in Durban, and AECI in Johannesburg.

For more information contact Keshin Govender, Siemens Southern Africa, +27 (0)11 652 2412, [email protected], www.siemens.co.za

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved