Rapid cooling of iron castings

July 2005

Maintenance, Test & Measurement, Calibration

A foundry that produces iron castings for the automotive industry had a problem with certain hot parts that slowed their production. After pouring, the castings gradually cool by travelling along a 60 m long conveyor. At the end, a shakeout conveyor breaks the sand mould so the castings can be removed. Normally, the operator could pick up the part with special gloves and grind the rough edges. However, some castings such as crankshafts, differentials housings, and shift parts retained too much heat, making them too hot to handle. The operator had to wait up to 10 minutes for them to cool.

The solution

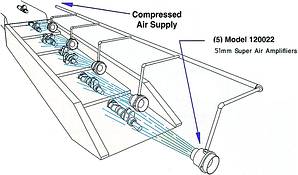

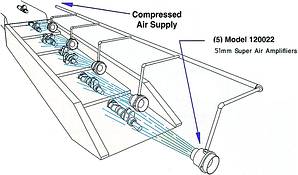

Five Exair model 120022, 51 mm super air amplifiers were installed over the shakeout conveyor. The high output from the air amplifiers rapidly cooled the parts without shocking them (no cracks or imperfections from too rapid cooling). When the parts reached the end of the conveyor, the operator could proceed immediately. The blockage was completely eliminated.

This manufacturer had almost given up on finding a cooling solution since fans and blowers showed little improvement. EXAIR Super Air Amplifier dramatically reduced the cooling time. The low cost EXAIR Super Air Amplifiers are compact, portable and have no moving parts to wear out (which is ideal in a dusty foundry). The patented design assures the highest air volumes possible with the lowest air consumption.

Further reading:

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...

Automated test and measurement

Comtest

Maintenance, Test & Measurement, Calibration

Comtest, in partnership with global brands, provides customised solutions with integrated hardware and software for efficient testing and data collection.

Read more...

Advanced field calibrator and communicator

Maintenance, Test & Measurement, Calibration

The Beamex MC6 is a high-accuracy field calibrator that offers automatic calibration capabilities for pressure, temperature and various electrical signals.

Read more...

Inline particle measurement

Mecosa

Maintenance, Test & Measurement, Calibration

Part of the SOPAT family, Parsum has for more than 20 years stood for the measurement of particles in a running process - without sampling and without a laboratory.

Read more...

Inline analysis measurement technology

Mecosa

Maintenance, Test & Measurement, Calibration

SOPAT develops and sells a photo-optical and image-based inline analysis measurement technology that quantitatively characterises particulate multi-phase systems. The software provides real-time analysis of particle size distribution.

Read more...