Foundation technology

March 2005

Fieldbus & Industrial Networking

Access Control & Identity Management

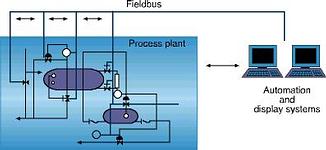

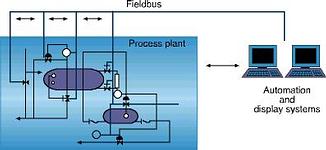

Foundation Fieldbus is an all-digital, serial, two-way communications system that serves as a local area network (LAN) for factory/plant instrumentation and control devices.

The fieldbus environment is the base level group of the digital networks in the hierarchy of plant networks. Foundation Fieldbus is used in both process and manufacturing automation applications and has a built-in capability to distribute the control application across the network.

Unlike proprietary network protocols, Foundation Fieldbus is neither owned by any individual company, nor regulated by a single nation or standards body. The technology is controlled by the Fieldbus Foundation, a non-profit organisation made up of many of the world's leading control and instrumentation suppliers - and end users.

While Foundation Fieldbus retains many of the desirable features of the 4 to 20 mA analog system, such as a standardised physical interface to the wire, bus-powered devices on a single wire, and intrinsic safety options, it offers a host of additional benefits to users. This article highlights the advantages of this bus system.

Device interoperability

With interoperability, one fieldbus device can be replaced by a similar device with added functionality from a different supplier on the same fieldbus network while maintaining specified operations. This permits users to 'mix and match' field devices and host systems from various suppliers. Individual fieldbus devices can also transmit and receive multivariable information, and communicate directly with each other over a common fieldbus, allowing new devices to be added to the fieldbus without disrupting active control.

Enhanced process data

Multiple variables from each device can be brought into the plant control system for archival, trend analysis, process optimisation studies, and report generation. This access to accurate, high-resolution data enables processes to be fine-tuned for better manufacturing throughput and reduced plant downtime. These efficiencies add up to higher plant performance and profitability.

Expanded view of the process

Modern fieldbus devices, with powerful, microprocessor-based communications capabilities, permit process errors to be recognised faster, and with greater certainty. As a result, plant operators are notified of abnormal conditions or the need for preventive maintenance, and can make better production decisions. Problems that detract from operating efficiency are more quickly corrected, enabling yields to go up while raw material costs and regulatory problems decrease.

Improved plant safety

Fieldbus technology helps manufacturing plants keep up with increasingly stringent safety requirements. By providing operators with earlier notification and warning of pending and current hazardous conditions, fieldbus allows for corrective action before an unplanned shutdown. Enhanced plant diagnostic capabilities also reduce the need for frequent access to hazardous areas, thus minimising the risks to field personnel.

Easier predictive maintenance

Enhanced device diagnostics capabilities make it possible to monitor and record such conditions as valve wear and transmitter fouling. Plant personnel are able to perform predictive maintenance without waiting for a scheduled shutdown, thus avoiding or reducing downtime.

Reduced wiring and maintenance costs

Foundation Fieldbus' use of existing wiring and multidrop connections provides significant savings in network installation costs. This includes reductions in intrinsic safety barrier termination and cable costs, particularly in areas where wiring is already in place.

Additional cost savings can be achieved through the decreased time required for construction and start-up, as well as simplified programming of control and logic functions using software control blocks built into fieldbus devices. More information on this subject is available from the Foundation Fieldbus site ( www.fieldbus.org).

Further reading:

Introduction to Part 2 loop signatures and process transfer functions

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Siemens sets new standards in drive technology

Fieldbus & Industrial Networking

Siemens is setting new standards in industrial drive technology with the launch of its new high-performance drive system, Sinamics S220. This offers a seamless and innovative drive system with comprehensive simulation and analysis capabilities and advanced connectivity features that enable full integration into digital work processes.

Read more...

2026 Industry Trends Report calls out security’s next opportunity

Integrated Solutions Access Control & Identity Management Perimeter Security, Alarms & Intruder Detection

Gallagher Security has released its 2026 Security Industry Trends Report, drawing on insights from end users, channel partners, consultants, and technology stakeholders; highlighting a growing opportunity for security to play a more strategic, value-driven role across organisations worldwide.

Read more...

PC-based control in the plastics industry

Beckhoff Automation

Fieldbus & Industrial Networking

Nissei Plastic, an injection moulding machine manufacturer based in Japan is implementing a worldwide tend towards open automation systems from experienced specialists using PC and EtherCAT-based control technology from Beckhoff.

Read more...

Loop Signature 31: Non-linearity in control loops (Part 2)

Michael Brown Control Engineering

Fieldbus & Industrial Networking

This article is a continuation of Loop Signature 30 published in the last issue in this series, exploring reasons for non-linearities which may be encountered in feedback control loops

Read more...

Smarter access, stronger defence

Secutel Technologies

Security Services & Risk Management Access Control & Identity Management Retail (Industry)

The holiday season brings excitement, increased foot traffic and, unfortunately, a spike in criminal activity targeting retail environments. Taking a proactive approach to security is essential in ensuring staff and assets remain safe.

Read more...

PC-based control optimises robotic parts handling on plastics machinery

Beckhoff Automation

Editor's Choice Fieldbus & Industrial Networking

NEO is a cartesian robot developed by INAUTOM Robótica in Portugal for parts removal on plastics machinery. Its aim is to increase system productivity. NAUTOM Robótica has entered into a strategic partnership with Bresimar Automação to increase the working speed of the cartesian robots using advanced control and motion solutions from Beckhoff. The result is a comprehensive, future-proof automation solution for its entire family of cartesian robots.

Read more...

PC-based control for flat wire motors for electric vehicles

Beckhoff Automation

Fieldbus & Industrial Networking

Special machine manufacturer, ruhlamat Huarui Automation Technologies unveiled the second generation of its mass production line for flexible stators with bar winding. This enables extremely short production cycle and line changeover times, supported by PC- and EtherCAT-based control technology from Beckhoff.

Read more...

Case History 200: The final case history – desuperheater control problem.

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

For this final article I have chosen to relate a problem that existed in a desuperheater temperature control on a boiler in a petrochemical refinery.

Read more...

PC-based control technology in additive manufacturing

Beckhoff Automation

Editor's Choice Fieldbus & Industrial Networking

As an open control platform, PC-based control supports different engineering approaches, including low-code programming. The machine builder, Additive Industries uses this to create the code for the TwinCAT runtime of its 3D printers.

Read more...