The list of VAS (value added services) offered by Endress + Hauser is substantial and one particular service that is coming to the fore is IMS (instrument management solutions). IMS is a consulting service aimed at assisting end users to develop and successfully implement working maintenance strategies. These maintenance strategies, targeted specifically at extending instrumentation assets life cycles, ensure high plant efficiency coupled with reduction in maintenance spending. One of the largest service contracts sold to date by Endress + Hauser, incorporating IMS, was recently implemented at a power plant in Germany.

The decision by Berlin-based energy provider Bewag to upgrade the Reuter and Reuter West combined heat and power plant resulted in Endress + Hauser supplying the entire measuring technology spectrum - not only were obsolete instruments replaced with new ones, but the entire process control system was changed.

"At the formative stages of this project, we decided to broach the subject of IMS with the customer," explains Grant Joyce, marketing manager, Endress + Hauser. "We set out to clarify that IMS would in no way encroach on the activities of their existing, in-house maintenance department. In fact, the maintenance management solution that we offered concentrated on aspects that the Bewag people themselves could not provide, but really needed."

During consultation, discussions pinpointed which maintenance services, as well as other services, contribute to the optimum functioning of the plant in the long-term. Individual tasks were defined and assigned to the customer, or Endress + Hauser. The entire package was developed from the ground-up, to ensure effectiveness and buy-in from departments and personnel. "We dealt mainly with the Maintenance and Process Control Technology department, but other departments, such as Production Planning, Measurement and Control Technology and Purchasing, were also involved," adds Joyce.

It was also important - right from the start - to identify the real requirements and find the right solutions for various parts of the overall plant. For example, the process control engineer was able to speak concretely about Endress + Hauser's support in updating software, thus improving plant efficiencies. This, in turn, enabled the engineer's superior to accurately budget for this module.

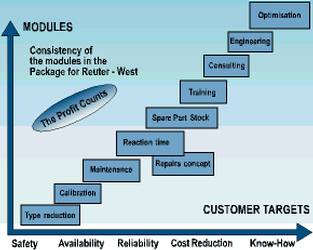

The end result is a tailor-made service package that sees Endress + Hauser responsible for ensuring that the measuring technology is compatible and kept up to date. It is comprised of six modules, ranging from consultation when selecting new instruments to the organisation of essential training for employees and maintenance services for analytical measuring technology. The modular approach allows the solution to match the customer's needs and also makes internal budgeting simpler.

"The ability to show the customer the benefit from the outset and deliver a packaged solution ensured our success. We are now integrated into internal processes and our know-how is of value to the customer in the long-term," Joyce concludes.

For more information contact Grant Joyce, Endress + Hauser, 011 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved