Monitoring of gas, oil and coal flames

September 2004

Maintenance, Test & Measurement, Calibration

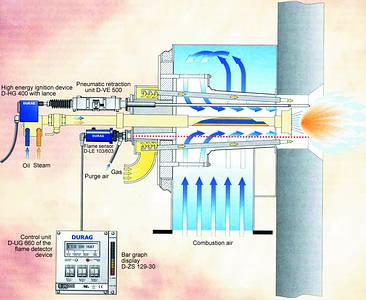

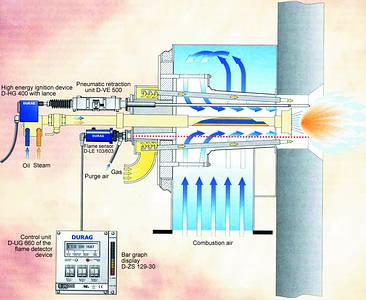

Durag's D-UG 660 control units, used in conjunction with the D-LE 603/103 flame sensors are ideal for monitoring UV and IR flames, even under difficult operating conditions. Suitable for use in furnace plants with several burners, the system offers a selection of adjustment options including 'flame on threshold', gain and 'high-pass filter frequency'.

After startup, the control unit performs a self-test that is repeated during operation, offering improved possibilities of flame signal evaluation and a higher grade of safety and availability. Each flame sensor has a test plug for connecting a digital display, making installation and adjustment easy. By displaying the current flame intensity, the flame sensors can be aligned optimally to the flame.

For interference-free transmission through extensive cable lengths, the flame sensors convert the flame signal into strong pulses that are transmitted to and counted by the control unit. The 'flame on' indication can be set in 100 steps, and extraneous light from adjacent flames will not interfere. Parallel connection between two optical flame sensors, either UV/UV, IR/IR or UV/IR are possible. Only signals corresponding to flame flickering are processed. Flame monitoring is not influenced by ambient light, and flames where UV radiation is absorbed by dust, water vapour or other materials may be monitored in the infrared range.

IR flame sensors with a sensitivity of up to 1800 nm have been operating successfully in monitoring gas and oil combustion systems employing NOx reduction techniques such as flue gas recirculation. Durag is represented locally by OEN Enterprises.

For more information contact Mauritz van Niekerk, OEN Enterprises, 011 675 4447, [email protected], www.oenenterprises.co.za

Further reading:

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...

Automated test and measurement

Comtest

Maintenance, Test & Measurement, Calibration

Comtest, in partnership with global brands, provides customised solutions with integrated hardware and software for efficient testing and data collection.

Read more...

Advanced field calibrator and communicator

Maintenance, Test & Measurement, Calibration

The Beamex MC6 is a high-accuracy field calibrator that offers automatic calibration capabilities for pressure, temperature and various electrical signals.

Read more...

Inline particle measurement

Mecosa

Maintenance, Test & Measurement, Calibration

Part of the SOPAT family, Parsum has for more than 20 years stood for the measurement of particles in a running process - without sampling and without a laboratory.

Read more...

Inline analysis measurement technology

Mecosa

Maintenance, Test & Measurement, Calibration

SOPAT develops and sells a photo-optical and image-based inline analysis measurement technology that quantitatively characterises particulate multi-phase systems. The software provides real-time analysis of particle size distribution.

Read more...