Dependable boiler water level monitoring

June 2003

Level Measurement & Control

Failure to detect low water levels in steam-raising plants can have costly and potentially disastrous consequences. Reliable water level detection is vital to prevent damage to the plant and its personnel. Modern boilers are designed to provide clean dry steam. Detection of incorrect water level in the drum is essential: too high a level can give wet steam, leading to turbine blade erosion, and if the level is too low, the boiler tubes can overheat, with the danger of explosion.

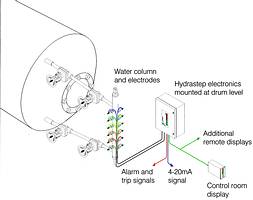

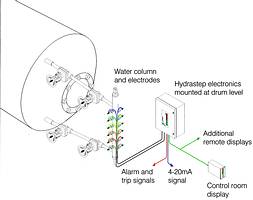

The Hydrastep electronic gauging system, manufactured by Solartron Mobrey and distributed in SA by Dupleix, is a 'fit and forget' solution to overcome the problems associated with unreliable, maintenance intensive gauge glasses. Hydrastep is fail-safe and fault tolerant.

The Hydrastep system consists of a water column fitted with up to 32 electrodes, an electronic measuring unit, local and remote displays, and connecting cables. Each of these components is available with a specification to provide outstandingly reliable, cost effective protection in any application.

Features include:

* Modular system to match requirements.

* Choice of 8 to 32 electrode resolution.

* Multiple remote displays.

* Up to 10 trips/alarms operable at selected water levels.

* Electrodes are continuously monitored for open or short circuit conditions.

* Fault indication on all displays.

* Multisegment LEDs provide built in redundancy.

* All signal path wiring continuously monitored.

* Dual independent power supplies provide fail operational condition.

* No junction boxes required - fully tested spliced cable as standard.

* Zero maintenance - fit and forget.

* No nuisance trips, no lost revenue.

* No missed incidents.

* Approved by insurance companies.

Hydrastep offers high levels of security. All measurements are interpreted as water, steam or contamination. Both short and open circuit conditions are detected and indicated as faults. Its makers claim a missing a trip condition amounting to less than 1 in 3 000 000 000, and that nuisance trips are less than 1 in 107.

For further information please contact Dave Rosser, DLM, 011 457 0500, [email protected], www.dlm.co.za

Further reading:

Precision in paper processing

VEGA Controls SA

Editor's Choice Level Measurement & Control

Paper manufacturing is a demanding process that relies on consistency, precision and control at every stage. The VEGABAR 82 pressure transmitter is well-suited to these harsh environments.

Read more...

Where every grain counts

VEGA Controls SA

Level Measurement & Control

VEGA’s advanced level and pressure measurement solutions offer transformative technologies to improve grain storage management in sub-Saharan Africa.

Read more...

Small, inexpensive radar level transmitters

VEGA Controls SA

Level Measurement & Control

Anyone who needs to keep processes running needs level measurement technology that measures reliably. However, what is needed is not always the most ‘fully featured’ solution, but the smartest one. This is exactly what VEGAPULS radar transmitters of the BASIC series do.

Read more...

Meeting the challenges of tank obstructions interfering with radar

Level Measurement & Control

One of the most challenging applications for non-contacting radar level transmitters is measuring level in tanks with internal obstructions, such as agitators, heating coils, pipes, ladders or baffles. Rosemount non-contacting radar level transmitters from Emerson feature an advanced solution that enables accurate and reliable level measurements in tanks with obstructions.

Read more...

A fresh approach to dairy processing

VEGA Controls SA

Level Measurement & Control

Ensuring the quality and safety of milk throughout the production process is of the utmost importance in the dairy industry. The VEGABAR pressure transmitters are suitable for hygienic applications. They are an asset in the dairy industry and have been used with success for measuring the milk level and the process pressure in storage tanks.

Read more...

Multiphase level measurement

Mecosa

Level Measurement & Control

The measurement of more than two phases or of interfaces that are not clearly defined poses a number of challenges for measurement technology. Radiation-based measuring systems such as Berthold‘s EmulsionSENS master these problems.

Read more...

Simple and efficient level measurement in the mining, minerals and metals industries

Endress+Hauser South Africa

Editor's Choice Level Measurement & Control

Measuring devices in the mining, minerals and metals industries face the challenge of varying material states and long distances in measurement height. Endress+Hauser’s answer to these challenges is the new Micropilot family.

Read more...

Level measurement of an acid dosing tank at a WWTP

Level Measurement & Control

Ferric chloride and other acids are essential chemical substances in water and wastewater treatment. To control the dosing of acid solutions, an Australian wastewater treatment plant uses a special container to store, mix and add these chemicals. The company opted in favour of KROHNE’s OPTIWAVE 1540 radar level transmitter

Read more...

Powering sub-Saharan Africa’s energy future

VEGA Controls SA

Level Measurement & Control

Crude oil storage plays an important role in the energy infrastructure of sub-Saharan Africa. The management of crude oil storage in comes with numerous challenges, including safety concerns, environmental conditions and infrastructural limitations.

Read more...

A new era in radiometric level and density measurement

Mecosa

Level Measurement & Control

The LoopSeries LB 430 radiometric detector from Berthold Technologies has a revolutionary power solution and sets new standards in level and density measurement.

Read more...