Empa (Swiss Federal Laboratories for Materials Testing and Research) conducts interdisciplinary energy research in the building and mobility sectors inside an actively used living and working environment on its campus. Empa relies on the OPC UA communication standard to interconnect its research infrastructure – three large-scale projects named ‘NEST,’ ‘ehub’ and ‘move’ plus all components involved in producing, storing, transporting and converting energy. Data communication – from control traffic between devices to data analysis in the cloud – is handled by CX5140 Embedded PCs running TwinCAT 3 OPC UA software.

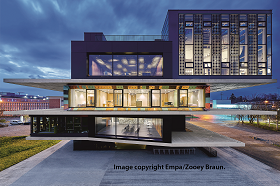

Empa, an interdisciplinary research institute and member of the ETH Domain – composed of university and research institutions – is working to bridge the gap between the laboratory and real-world applications. One primary focus of its work is on energy and sustainable building technologies based on research and technology transfer platforms called demonstrators. These include the Next Evolution in Sustainable Building Technologies (NEST), the Energy Hub (ehub) and the demonstrator for future mobility (move). Working in close collaboration with research and industry partners, Empa uses these largescale building, mobility and energy projects to deliver market-ready solutions in those sectors.

Open, clearly defined interfaces with PC-based control and OPC UA

Given that Empa’s demonstrators are available to a wide range of users, it was essential to create an open, manufacturer-independent platform with clearly defined interfaces, according to Philipp Heer, ehub Group Leader at Empa: “The units have just a single physical link to the NEST backbone that connects them with the thermal and electrical systems. Each unit operates independently and incorporates its own automation solution, which communicates via Ethernet. The challenge here is to integrate new units into the demonstrator infrastructure with as few limitations as possible so that systems can be maintained by service technicians and used safely and to their fullest potential for research purposes as well. From an integration point of view, flexibility is essential because the system boundaries shift whenever we add a new unit.”

Enabling flexible access from outside the Empa campus was another challenge. To achieve this, the process control level was implemented in the cloud rather than on internal servers. In addition to other requirements, this called for a specialised control system software architecture that would ensure safe system operation yet allow actuator override where necessary for research purposes. For Heer, OPC UA was the ideal communication technology to meet the requirements for a highly complex and flexible system of this kind: “We use OPC UA across the board, for everything from device-to-device communication at the control level all the way up to data analysis in the cloud and research integration. We developed an OPC UA information model specifically for this purpose. This model lets us integrate new units and components based on standardised specifications. To keep the integration effort as low as possible and ensure consistency, we incorporated parts of the software architecture into the OPC UA information model itself. This approach also allows us to implement new Internet of Things (IoT) software and services without having to adapt the system.”

Embedded PCs with TwinCAT OPC UA drive data communications

Ten CX5140 embedded PCs running TwinCAT OPC UA software (TF6100) control the communication among Empa’s three demonstrators. Heer explains: “We have seven CX5140s operating on the NEST backbone as TwinCAT OPC UA servers and clients that we use to connect heating, ventilation and room automation systems. The other three embedded PCs work as central management systems in NEST to hook up the micro grid and integrate the units. The system as a whole monitors some 60 000 OPC UA objects, including a number of data point instances needed for building automation or to provide researchers write access. Around 6000 relevant sensor signals from these objects are logged straight to a database. Despite the scale and scope of the system, there have been no performance issues so far. The TwinCAT OPC UA Gateway offers a distinct advantage here: It provides a central point of access to the entire information model, where each sensor is mapped to a corresponding structure. With this setup, all of the information contained in the database and from integrated systems such as LabVIEW can be accessed easily through a single interface.”

Another valuable feature from Heer’s perspective is that the classic building automation system, implemented using the TwinCAT Building Automation Library, can be manipulated directly over OPC UA: “We can override any individual actuator to suit the needs of specific research projects. TwinCAT OPC UA lets us create new instances elegantly and easily within the information model’s tree. Researchers are only able to see their own particular tree – in much the same way as the building automation system can only see its own tree for normal operating purposes. We can choose and apply the requisite permissions via a selector implemented in the Beckhoff control system. This is both extremely flexible and fast, which is a huge advantage.”

Flexibility – the core advantage of PC-based control

Empa began using PC-based control technology from Beckhoff in 2013 – initially, to automate a small research building equipped with a large number of different interfaces. Says Heer: “One important factor besides the compact design was the variety of interfaces, which went well beyond the usual array of building technology standards like DALI, KNX or M-Bus. The building relied on additional industrial communication protocols, which we also had to accommodate. The project called for a mix of Bus Terminals and EtherCAT Terminals, which was not a problem with Beckhoff technology. The outstanding communication performance of EtherCAT is another big advantage for us, especially in situations that require exceptionally precise measurements.”

A further benefit of PC-based control is that it allows the seamless integration of energy measurement technology. For instance, Empa uses around 25 EL3403 and EL3443 EtherCAT three-phase power measurement terminals to record and analyse key electrical data in its supply network. TwinCAT Scope also makes work even easier. Heer concludes: “With TwinCAT Scope’s ease-of-use and powerful analysis capabilities, we can test controllers using high-resolution data and evaluate disturbance inputs exceptionally well.”

For more information contact Michelle Murphy, Beckhoff Automation, +27 11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved