The one cable automation (OCA) philosophy from Beckhoff is based on the connection of individual field devices, decentralised terminal boxes, and even machine modules, using only one cable. This cable technology combines ultra-fast communication via EtherCAT with the power supply required by the connected components. For the 24 V field level, this was implemented using the Ether-CAT P technology expansion connected via special M8 connectors. To provide additional power supply capabilities via a one cable solution, Beckhoff developed the new ENP and ECP connector families. These combine EtherCAT or Ether-CAT P communication with additional power conductors in one cable, and are easy to use, mechanically coded to prevent installation errors and offer a high protection rating of IP67.

The one cable automation (OCA) philosophy from Beckhoff is based on the connection of individual field devices, decentralised terminal boxes, and even machine modules, using only one cable. This cable technology combines ultra-fast communication via EtherCAT with the power supply required by the connected components. For the 24 V field level, this was implemented using the EtherCAT P technology expansion connected via special M8 connectors. To provide additional power supply capabilities via a one cable solution, Beckhoff developed the new ENP and ECP connector families. These combine EtherCAT or EtherCAT P communication with additional power conductors in one cable, and are easy to use, mechanically coded to prevent installation errors and offer a high protection rating of IP67.

OCA has an exceptionally flexible design that is ideal for use in a broad range of applications. Different sections in a network can be connected by selecting a suitable one cable solution for devices and components according to their individual power requirements. The unrestricted openness for mixed network topologies is a key benefit which enables flexible transitions between:

• EtherCAT P communication with integrated power supply (one cable solution with M8 connector).

• A one cable solution using hybrid cables that combine an EtherCAT or EtherCAT P communication element with additional power conductors (one cable solution with the new ENP or ECP connectors).

• A conventional two cable solution with separate power supply (EtherCAT via M8/RJ45 connector or EtherCAT/EtherCAT P via ENP/ECP connector).

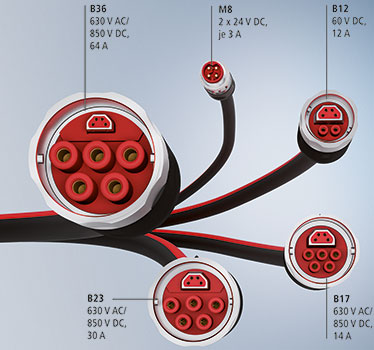

The new ECP and ENP connector series implement the combination of communication and power elements in different performance classes that range from 3 A to 64 A, all in an extremely compact design. The system is a completely new product development and meets the full scope of OCA requirements regarding connected devices and modules, including drives, sensors/actuators, control cabinets and entire machine modules. Reducing the system to the essentials – namely the EtherCAT or EtherCAT P communication element and DC or AC power supply lines – creates a cost-effective connection concept. In addition, the system is easy to use due to the bayonet connections with mechanical and colour coding. The ECP variant for EtherCAT P also provides another benefit: the power transmission integrated into EtherCAT P enables the elimination of the four wires normally required for 2 x 24 V. This allows the use of thinner, lower-cost cables and alternatively, the supply of other voltages.

EtherCAT P as an OCA solution for 24 V I/O systems

With EtherCAT P, Beckhoff has expanded the globally established EtherCAT technology to combine ultra-fast EtherCAT communication with a 24 V system and peripheral power supply, all in a standard Ethernet cable. Beckhoff developed special M8 connectors for EtherCAT P with mechanical encoding that eliminates possible confusion with connectors used for standard EtherCAT slaves.

The design of a specific machine or plant installation is simplified using a TwinCAT software tool that helps specify all individual EtherCAT P consumers and cable lengths to configure the highest performance and most cost-effective EtherCAT P network. For that purpose, the new and compact EPP9022-0060 EtherCAT P Box module, with dimensions of only 30 x 86 x 26.5 mm, can be used to gather important data. This module measures the Us and Up voltages along with the Is and Ip currents in the system and passes the information on to the controller. Provided the system has the data from all consumers, it can also take the individual devices’ power consumption over time into account. For example, if two actuators never switch at the same time for logical reasons, this can be taken into account when configuring the maximum current. This introduces additional savings potential with regard to the required number of power supply feeds and power supply units.

Connector series for EtherCAT and EtherCAT P

If higher power or additional supplies are required in addition to the 24 V system and peripheral power supply via EtherCAT P, power can be supplied via corresponding hybrid cables together with the ECP and ENP connector series developed by Beckhoff for this purpose:

• ECP (EtherCAT P + Power): This connector series combines a compact, trapezoidal EtherCAT P element (using the same pin allocation as the EtherCAT P encoded M8 connector) with additional power pins. In this way, the 24 V supply integrated into EtherCAT P is complemented with an additional power supply line.

• ENP (EtherCAT/Ethernet + Power): These connectors combine a trapezoidal, central communication element with additional power pins in the same way as ECP. The trapezoidal element has an inverse design to prevent incorrect connections and provides data transmission via EtherCAT, standard Ethernet or other Ethernet-based communication protocols.

Different connector sizes from B12 to B36 are available with a varying number of power pins (2 to 6), so that they can be easily adapted to the requirements of different network types and the power consumption of connected consumers. The complete and full-length 360° shielding of the central trapezoidal element continues the typical high performance of EtherCAT. Furthermore, the compact design also provides adequate space for the power pins, ensuring high current-carrying capacity and dielectric strength. The quick and easy-to-use bayonet connection, along with the broad flange spectrum in the diverse housing variants for rear panel, front panel and square installation, provide additional user benefits. Additionally, there are versions for field assembly that enable time saving during installation.

Broad range of applications

The ECP and ENP connector families, together with the EtherCAT P-encoded M8 connector type, cover all applications from 24 VDC on the I/O level to drive systems with 480 VAC and a maximum of 64 A. The flexibility of the connection system is available in every application area: depending on specific needs, EtherCAT, EtherCAT P or a mixture of both can be used. Typical engineering requirements for small and mid-sized systems are covered by EtherCAT P with up to 3 A for Us and Up in combination with M8 or ECP connectors. In contrast, the ENP connector series is the ideal solution for larger installations involving longer transmission distances. The same also applies for applications without EtherCAT P, such as an endpoint with a 24 V power supply unit or for the supply of 24 V consumers with very high power demands.

Expanding the OCA concept through the growing diversity of the EtherCAT P, ECP and ENP devices and components constantly expands the range of application options for users. Current examples are the two new infrastructure box modules EP9221-0057 (1 channel) and EP9224-0037 (4 channel) from Beckhoff. Via B17-ENP connectors, these power distributors provide two 24 V supplies and a protective conductor along with EtherCAT communication in the trapezoidal element. The power cable has a cross-section that is approximately five times larger than the EtherCAT P element and can bridge longer distances or conduct significantly higher currents, up to 20 A at ambient temperature.

For more information contact Michelle Murphy, Beckhoff Automation, +27 (0)11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved